Analysis of Potential Water Inflow Rates at an Underground Coal Mine Using a WOA-CNN-SVM Approach

[ad_1]

1. Introduction

The WOA-CNN-SVM prediction model is constructed by selecting multifactor evaluation indexes based on coal mine geological data, which can efficiently predict aquifer water yield with small samples. Compared with other models, this model has higher evaluation accuracy. It can be used to predict the water yield of an area in the absence of unit water inflow rate data and can more accurately portray the spatial dynamic characteristics of water yield.

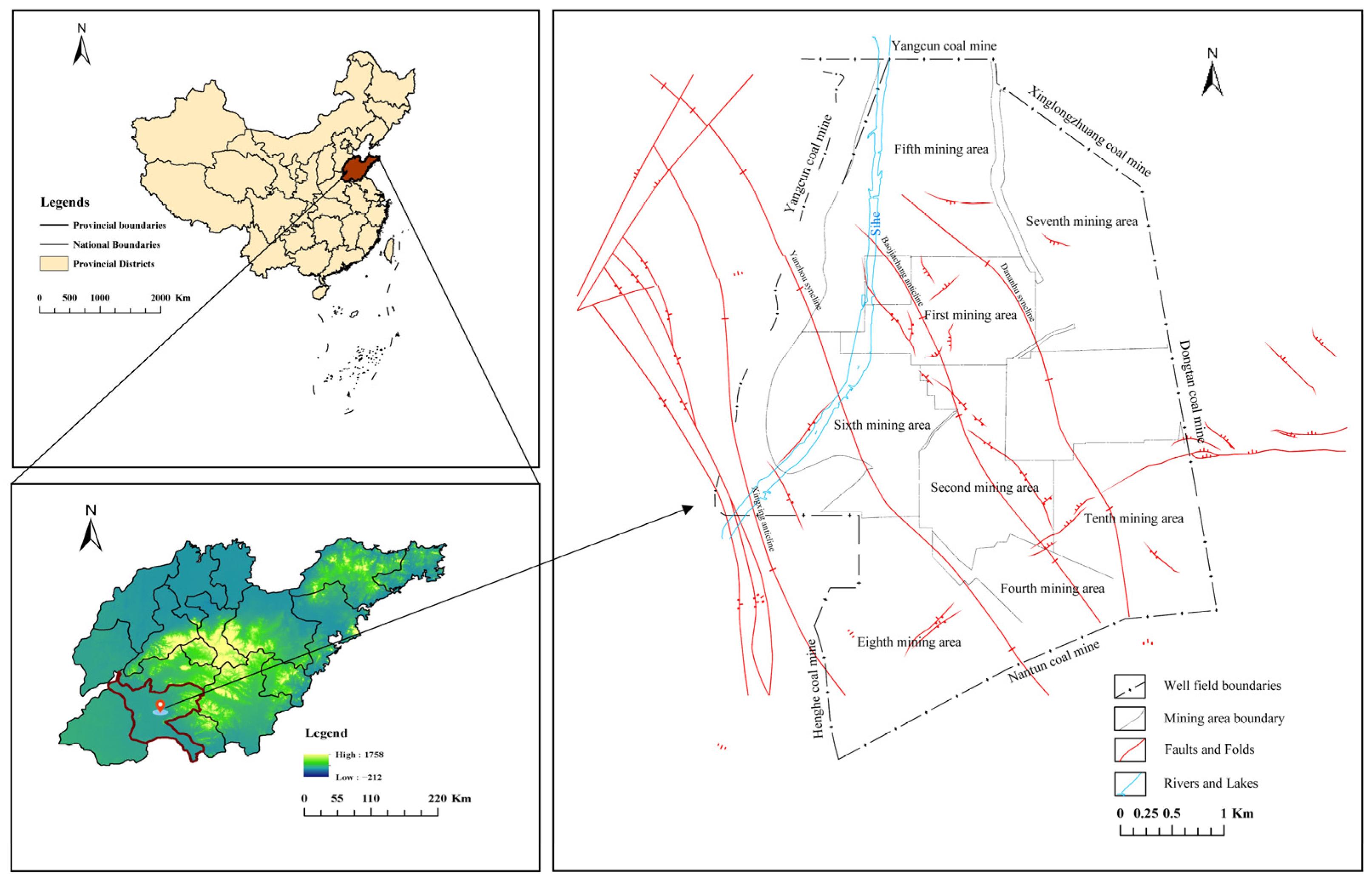

2. Overview of Baodian Coal Mine

The study area is located in the Jining City area, Shandong Province, and the stratigraphy from top to bottom is Quaternary (Q), Jurassic, (J), Permian (P), Carboniferous (C), and Ordovician (O). The total thickness of the Quaternary layer, composed of brownish yellow, gray-green to gray-white clay, sandy clay, clayey sand (gravel), and sand and gravel layers, is 110~228 m, with an average thickness of 171 m, thin in the southeast and thick in the northwest, and divided into the upper, middle, and lower groups, with average thicknesses of 59 m, 67 m, and 41 m, respectively. The water-bearing layer and water-isolating layer are interlaced with each other, the lenticular body is relatively developed, and the lithology is complicated. The main aquifer is the water-yielding layers of the lower group of sand and gravel layers, which are mainly distributed in the middle, western, and middle-north part of the coal field and are missing in the southeast part of the coal field, which is mainly the alluvial flood layer.

The coal field in the study area belongs to the simple tectonic type. The southern flank is cut by the Huangfu fault, while the northern flank is relatively intact. The stratigraphy of the coal field is undulating, and the folds are characterized by wide and slow short-axis dips, with dips ranging from 2° to 13°, and the dips only vary greatly in local areas (up to 27°). Except for the southern boundary fault (Huangfu fault), the southwestern boundary fault (Majialou fault), and the Puzi fault in the northern part of the coal field, the other faults all have a drop of less than 30 m.

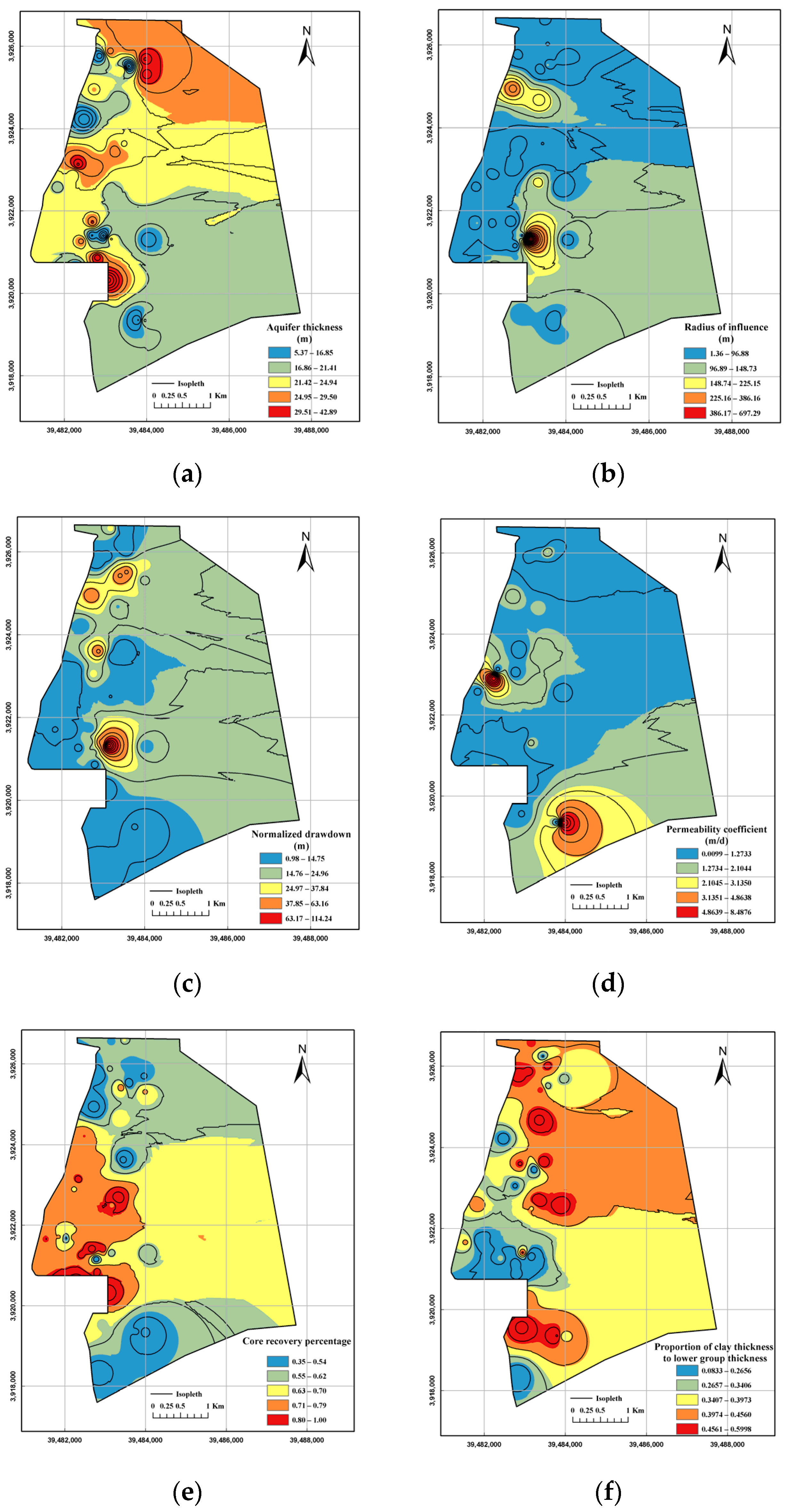

3. Determination of the Main Controlling Factors of Water Inflow

The measurement of water content depends on the unit water inflow rate, and the lack of data makes it impossible to describe the water yield globally. Therefore, by analyzing the influencing factors of water yield, the water yield prediction model is established. Through training the existing data, the results are compared with the actual aquifer pumping test results, which can effectively evaluate the water yield degree of mines lacking the actual inflow data.

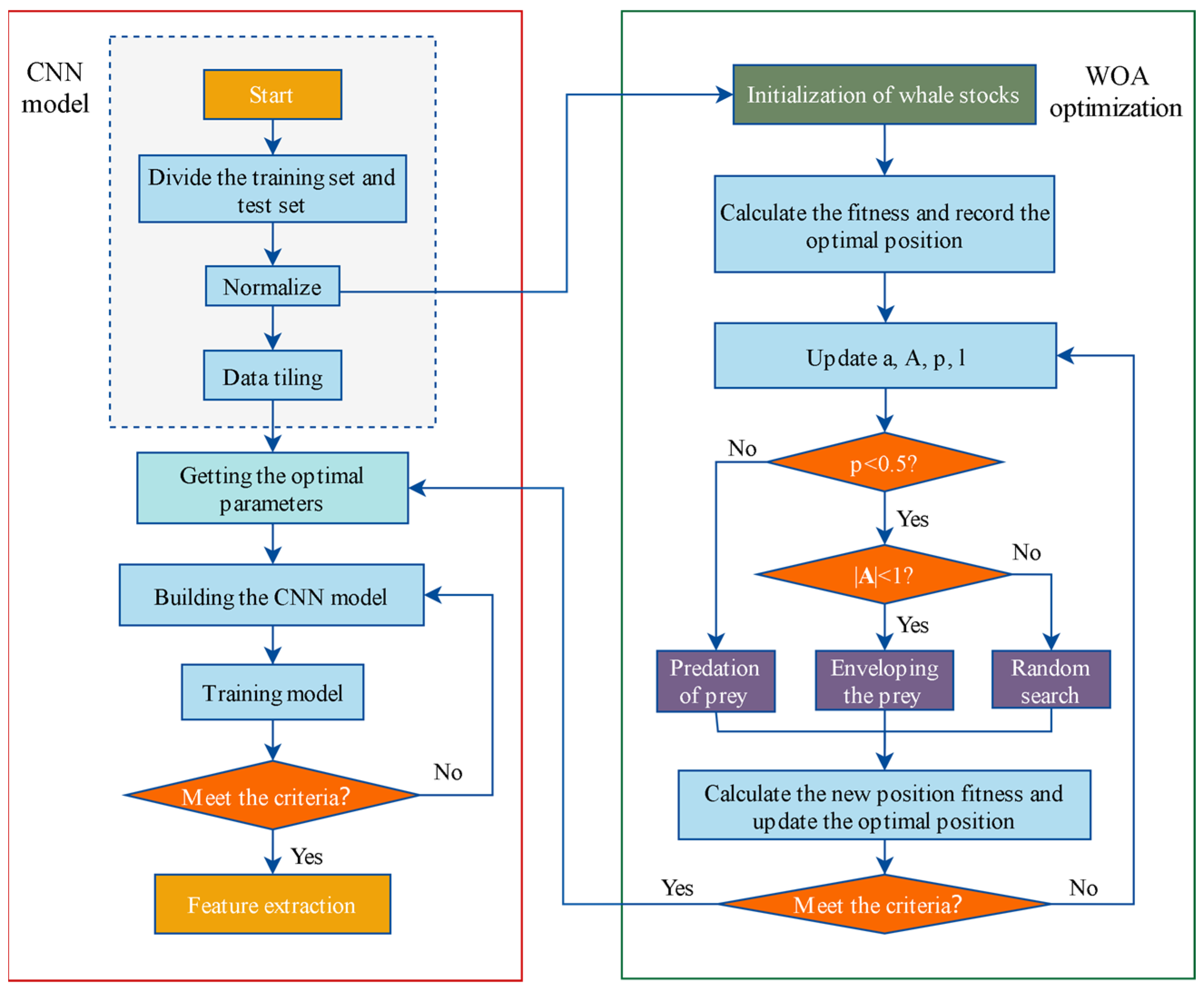

4. Composite Modeling Framework

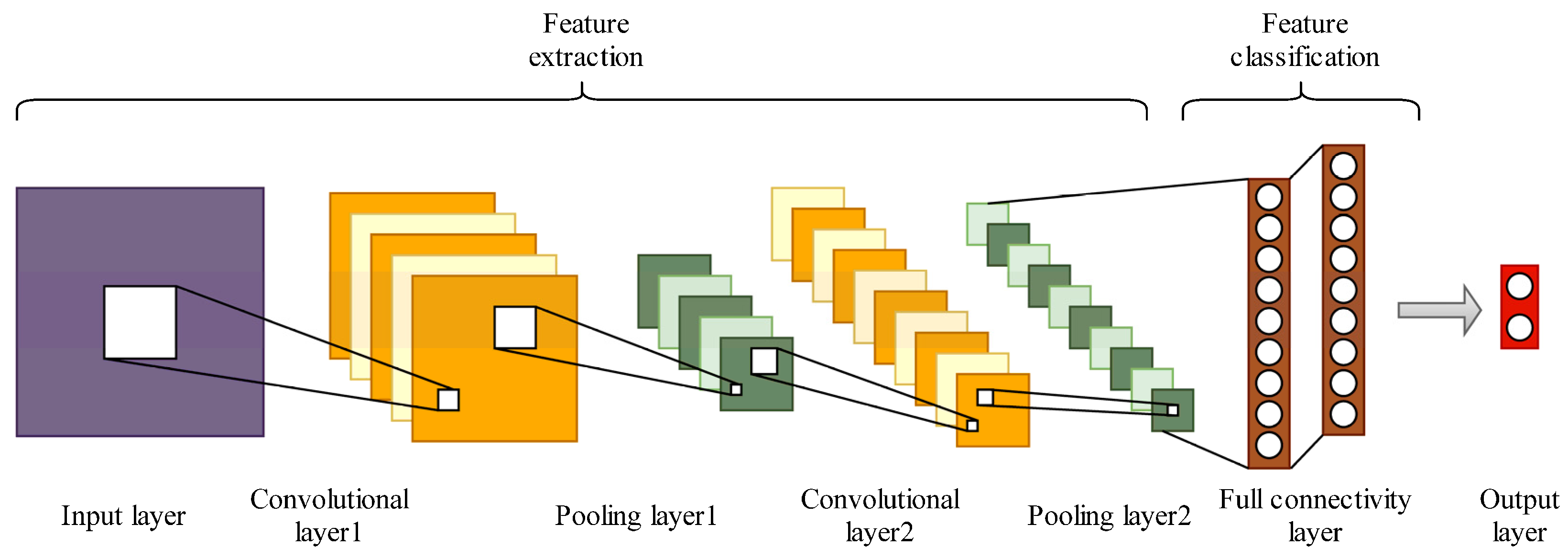

4.1. Convolutional Neural Network Modeling Framework

4.2. Support Vector Machine Model

where: is the high-dimensional feature space; is the nonlinear mapping; is the threshold value.

where: and are relaxation factors; is the insensitivity loss factor; is the penalty factor; is the corresponding output of .

where: and is Lagrange operator; is the kernel function.

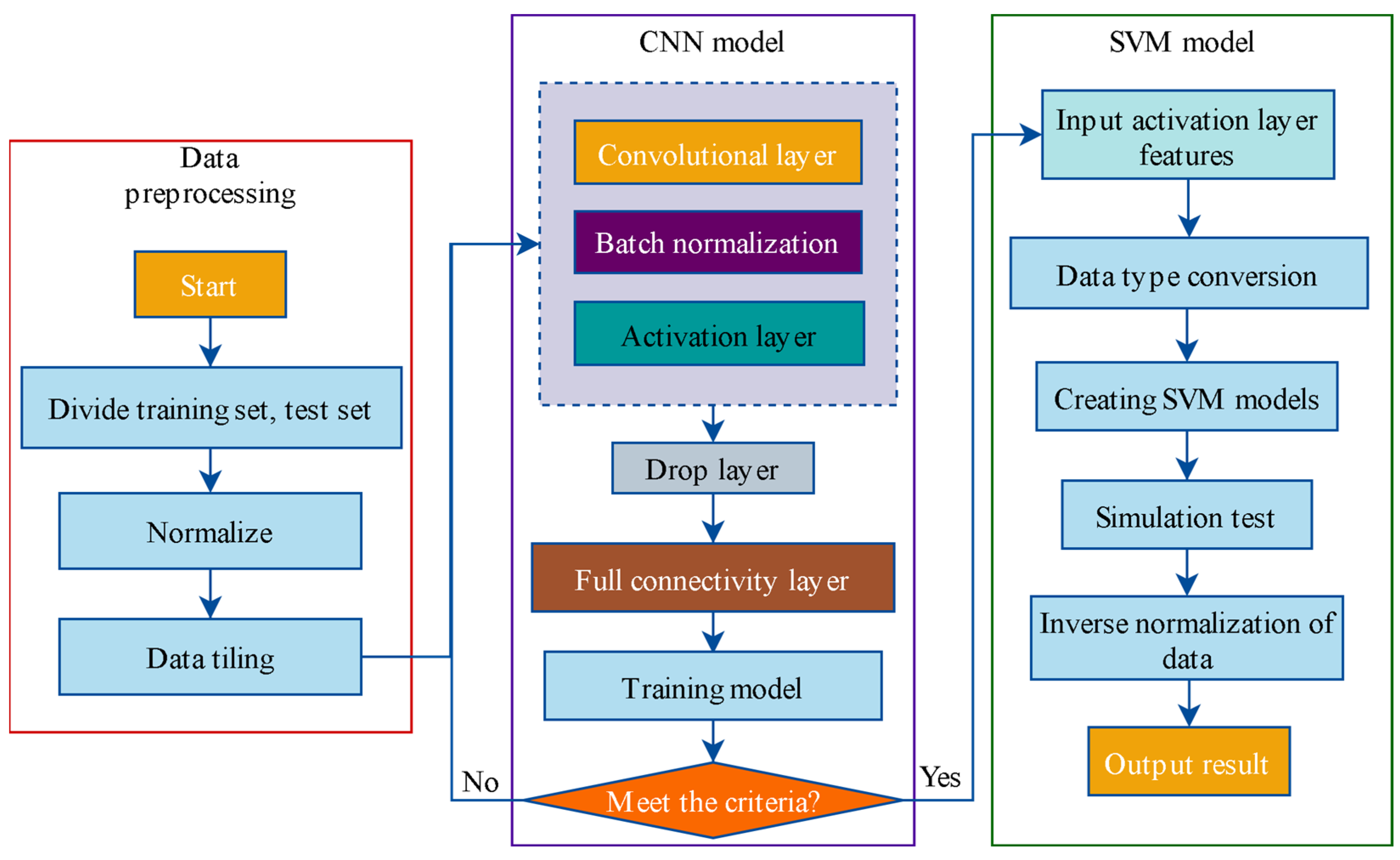

The prediction steps of the CNN-SVM model are: (1) normalize the data to eliminate the effect of magnitude, divided into a training set and test set, to comply with the model’s need to preprocess the data by tiling; (2) input the training set to the CNN model for training and select the ReLU function as the activation function to achieve the convergence effect and save it; (3) use CNN-extracted feature vectors as the input to the SVM classifier to continue to train; (4) substitution of the test set into the trained model outputs the water yield prediction results and measurement of the accuracy of the predictive model by the prediction results and comparison with the real value.

4.3. Whale Optimization Algorithm

where: is the distance between the search agent and the prey; and are the coefficient vectors; is the position vector of the global optimal solution, updated in each iteration; is the position vector; and denotes the number of current iterations.

where: is the convergence factor, which decreases linearly from 2 to 0 during the iteration; , is a random vector distributed between [0, 1].

where: denotes the best distance obtained; is a constant defining the shape of the logarithmic spiral; is a random number in [−1, 1]; is a random number in [0, 1].

where: is the randomly selected whale position.

where: is the normalized data; is the original data; is the -th value of the original data.

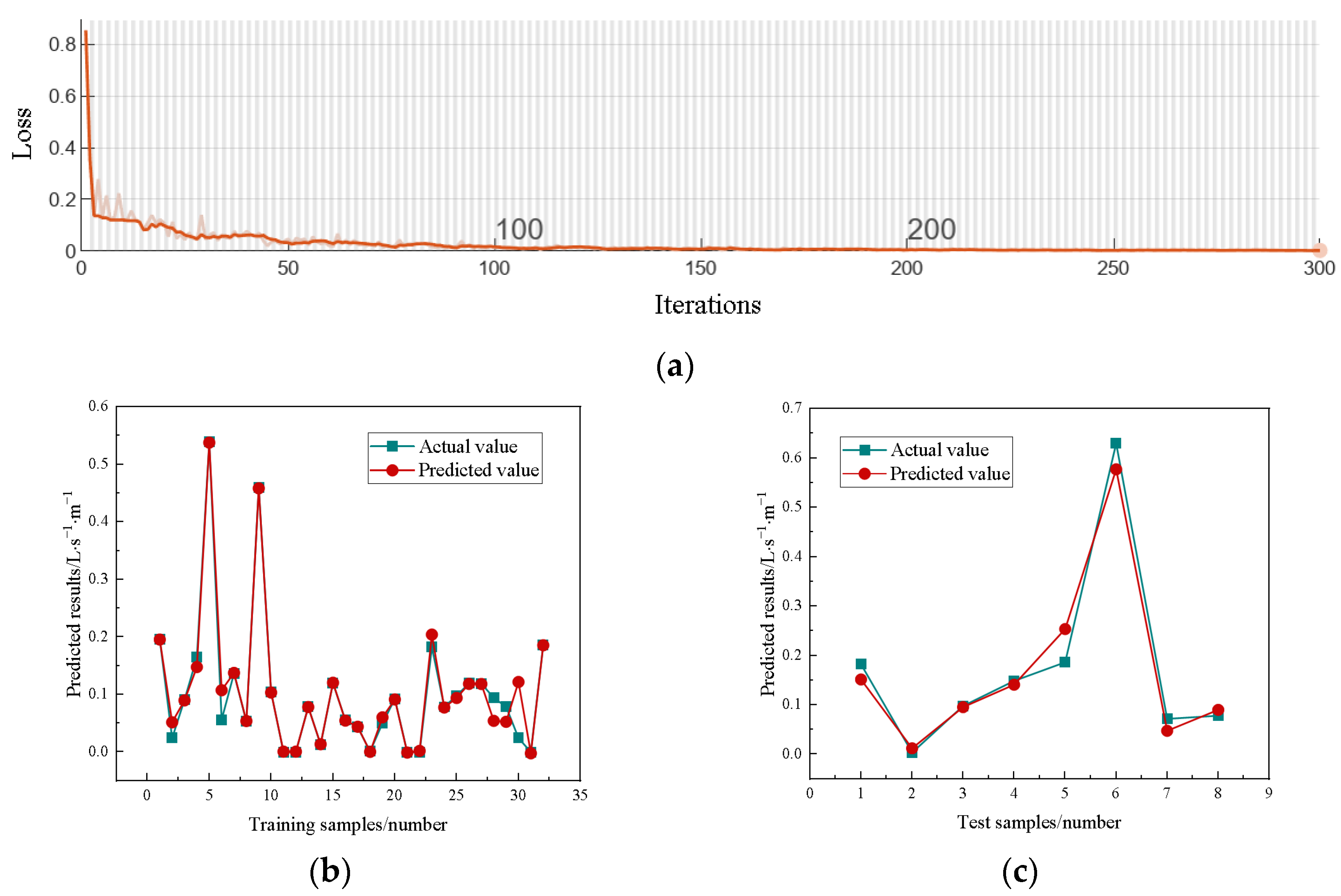

5. Model Construction and Validation

5.1. Model Construction

where: is the number of samples; is the true value; is the predicted value.

The RMSE of the training set and test set are 0.0269 and 0.0318, respectively. The MAE is 0.0125 and 0.0268, respectively, which is a good prediction effect, and there is no overfitting phenomenon. The model can be applied to the prediction of water yield.

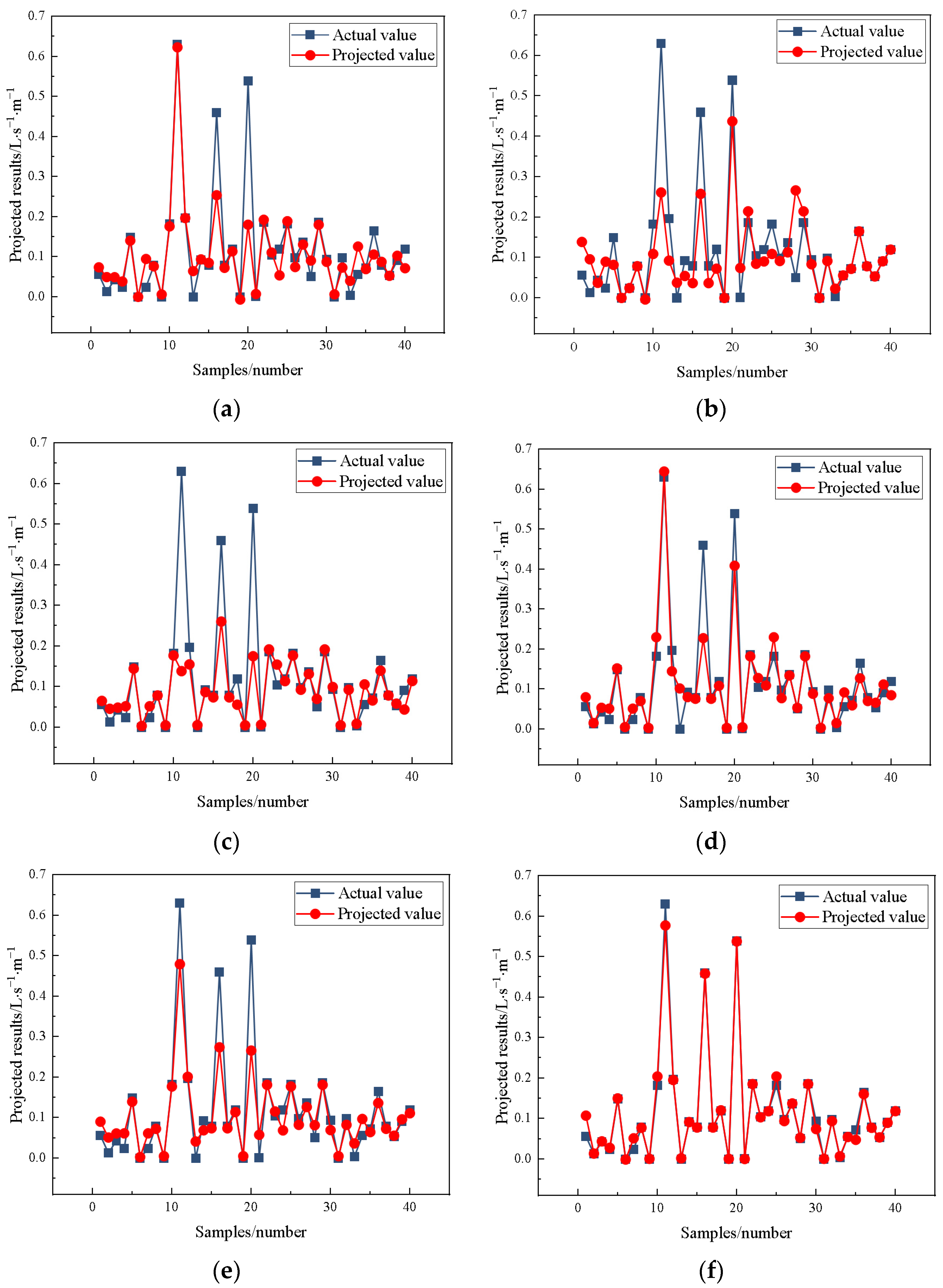

5.2. Model Prediction Performance Testing

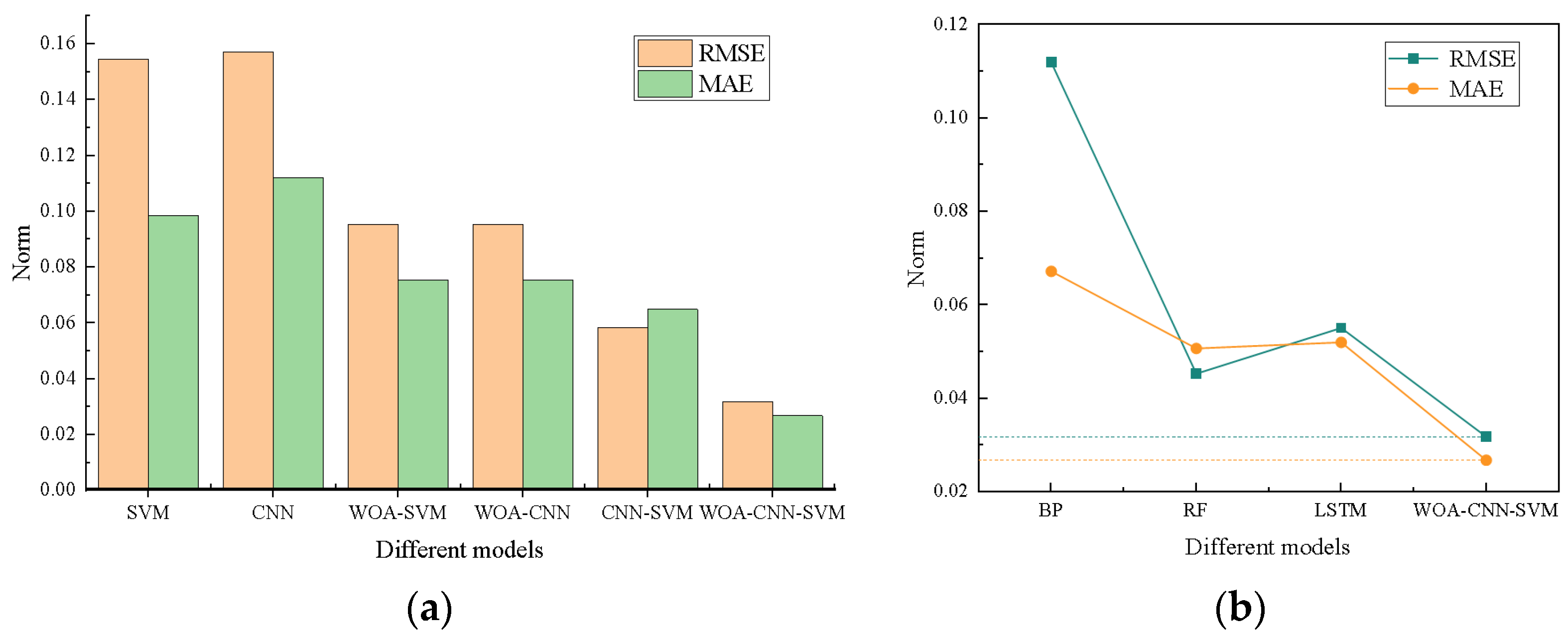

To test the effectiveness of the model optimization results, the same set of borehole data is used as training and testing samples, and the unoptimized machine learning models SVM, CNN, WOA-SVM, WOA-CNN, and CNN-SVM are selected for comparison.

The composite model showed high performance, followed by random forest networks. The BP neural network exhibits less stable predictive performance. These results indicate that the automatically learned data features of the water yield prediction model based on WOA-CNN-SVM can more effectively characterize the mapping relationship between the unit water inflow rate and the influencing factors, thus obtaining a higher prediction accuracy.

6. Discussion

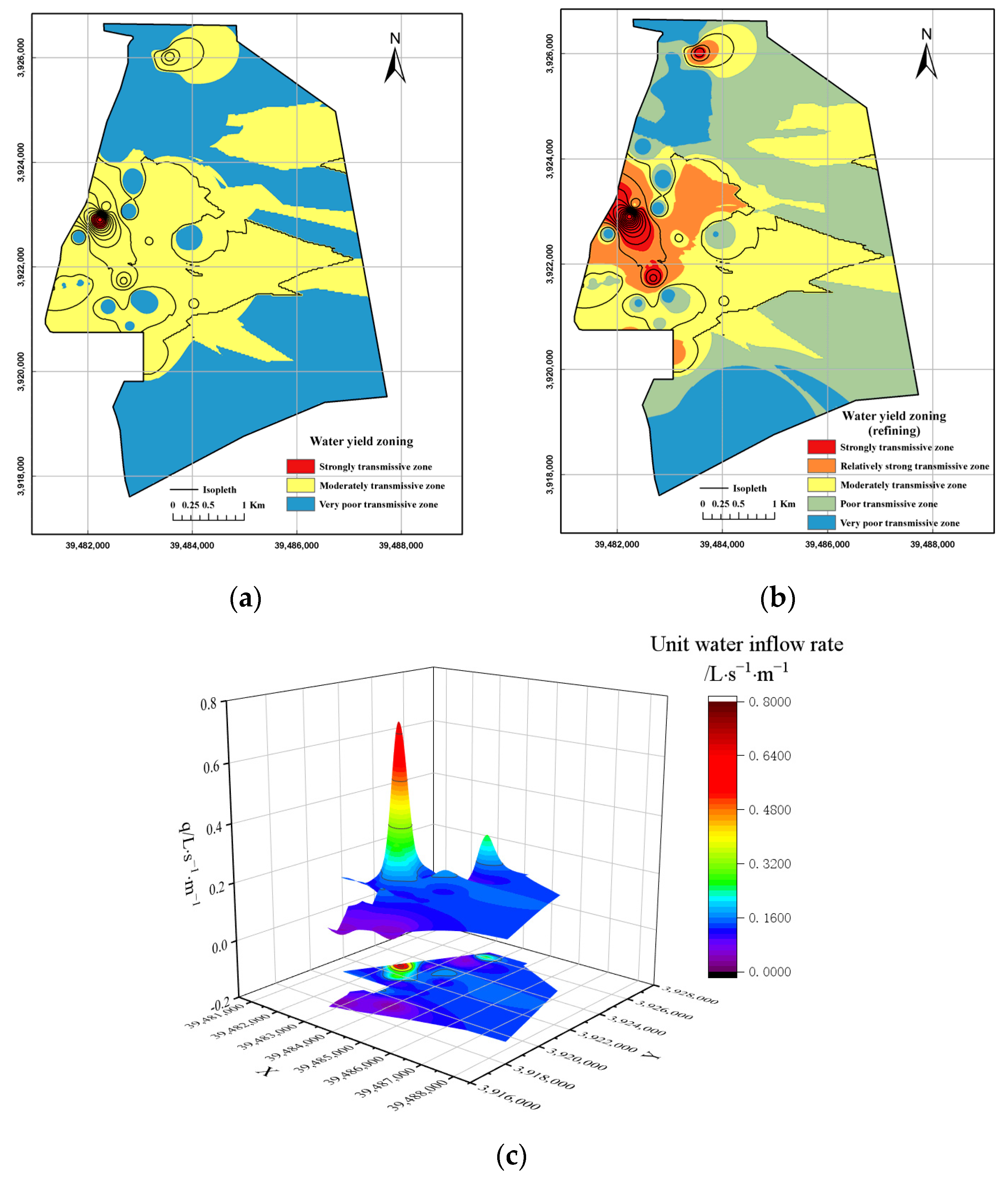

6.1. Water Yield Zoning Predictions

6.2. Strengths and Limitations

The important achievement of this study is to put forward a compound prediction model, which can provide a new idea for readers to accurately and reliably evaluate the water yield of aquifers in mining areas to guide coal mining. The limited borehole data and dimensions of main control factors may be the main reason for the error between the predicted results and the actual values. In the future, we can rely on the advantages of big data to realize data sharing and make the model more suitable for water yield prediction through more data training.

7. Conclusions

In order to investigate the water yield of aquifers that pose a threat to coal mine safety production, the water yield in the study area was predicted and categorized based on mine borehole exploration data using the WOA-CNN-SVM prediction model, with a representative coal mine selected. The main conclusions are as follows:

- (1)

-

The combination of CNN and SVM models improves the correct rate of prediction results by about 24%, showcasing strong generalization ability. In addition, after applying the whale optimization algorithm, the prediction correctness is significantly improved. The whale optimization algorithm demonstrated remarkable global search ability, preventing it from becoming trapped in local optima and enhancing the accuracy of water yield prediction. Additionally, it overcame the issue of requiring a large number of samples in traditional methods and effectively addressed data scarcity caused by a limited number of pumping holes. Therefore, it proved feasible to predict water yield levels.

- (2)

-

A multifactor composite water yield prediction model for aquifers was developed, using aquifer thickness, influence radius, water level drop, permeability coefficient, borehole coring rate, and the ratio of clay thickness to the lower group thickness as evaluation criteria. Compared with the unoptimized model and other models, the WOA-CNN-SVM model has significantly lower root mean square error and mean absolute error.

- (3)

-

Based on the validation of the provisions of the water control regulations, the predictions are in accordance with the regulations. It also carries out the delineation of water yield areas relative to the interior of the mine. The northern part of the fifth mining area and the north-central part of the sixth mining area in the study area displayed relatively strong water yield, with well-developed aquifers in the northern section. Conversely, the southern part of the eighth mining area exhibited generally weak water yield, with the middle group of the Quaternary system well-developed and stable, effectively blocking the hydraulic connection between the upper and lower Quaternary aquifer groups. As a result, the water yield of individual aquifers in that area was moderately weak. Comparisons within the mining region are similarly realistic, signifying the feasibility of the water yield prediction model based on WOA-CNN-SVM.

Author Contributions

W.L.: Investigation, Methodology, Writing—original draft, Writing—review and editing. Y.R.: Data curation, Investigation, Methodology, Project administration, Writing—original draft. X.M.: Investigation, Methodology, Writing—original draft, Writing—review and editing. B.T.: Investigation, Writing—original draft. X.L.: Investigation. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Natural Science Foundation of Shandong Province (ZR2023ME002) and the SDUST Research Fund (grant 2018TDJH102).

Data Availability Statement

All data analyzed during the study are included in the submitted article.

Conflicts of Interest

Author Bo Tian was employed by the company Shandong Energy Group Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Wu, Q.; Tu, K.; Zeng, Y.F.; Liu, S.Q. Exploration of the main problems and countermeasures for creating an upgraded version of China’s main energy source (coal). J. China Coal Soc. 2019, 44, 1625–1636. [Google Scholar]

- Zeng, Y.; Meng, S.; Wu, Q.; Mei, A.; Bu, W. Ecological water security impact of large coal base development and its protection. J. Hydrol. 2023, 619, 129319. [Google Scholar] [CrossRef]

- Zhao, Y.; Wu, Q.; Chen, T.; Zhang, X.; Du, Y.; Yao, Y. Location and flux discrimination of water inrush using its spreading process in underground coal mine. Saf. Sci. 2020, 124, 104566. [Google Scholar] [CrossRef]

- Zhang, C.; Jin, Z.; Feng, G.; Song, X.; Rui, G.; Yujiang, Z. Double Peaked Stress–Strain Behavior and Progressive Failure Mechanism of Encased Coal Pillars Under Uniaxial Compression. Rock Mech. Rock Eng. 2020, 53, 3253–3266. [Google Scholar] [CrossRef]

- Qiu, M.; Yin, X.; Shi, L.; Zhai, P.; Gai, G.; Shao, Z. Multifactor Prediction of the Water Richness of Coal Roof Aquifers Based on the Combination Weighting Method and TOPSIS Model: A Case Study in the Changcheng No. 1 Coal Mine. ACS Omega 2022, 7, 44984–45003. [Google Scholar] [CrossRef] [PubMed]

- Bi, Y.; Wu, J.; Tang, L.; Zhai, X.; Huang, K.; Liu, W. Water Abundance Comprehensive Evaluation of Coal Mine Aquifer Based on Projection Pursuit Model. Lithosphere 2022, 2021, 3259214. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, H.; Qi, Z. An application of nonlinear fuzzy analytic hierarchy process in safety evaluation of coal mine. Saf. Sci. 2016, 86, 78–87. [Google Scholar] [CrossRef]

- Xu, Y.; Ma, L.; Yu, Y. Water Preservation and Conservation above Coal Mines Using an Innovative Approach: A Case Study. Energies 2020, 13, 2818. [Google Scholar] [CrossRef]

- Ma, J.; Dai, H. A methodology to construct warning index system for coal mine safety based on collaborative management. Saf. Sci. 2017, 93, 86–95. [Google Scholar] [CrossRef]

- Long, R.; Li, H.; Wu, M.; Li, W. Dynamic evaluation of the green development level of China’s coal-resource-based cities using the TOPSIS method. Resour. Policy. 2021, 74, 102415. [Google Scholar] [CrossRef]

- Mahdevari, S.; Shahriar, K.; Esfahanipour, A. Human health and safety risks management in underground coal mines using fuzzy TOPSIS. Sci. Total. Environ. 2014, 488–489, 85–99. [Google Scholar] [CrossRef]

- Hwang, S.-H.; Mangalathu, S.; Shin, J.; Jeon, J.-S. Machine learning-based approaches for seismic demand and collapse of ductile reinforced concrete building frames. J. Build. Eng. 2021, 34, 101905. [Google Scholar] [CrossRef]

- Luan, L.-T.; Ha, N.-T.-V.; Lee, J.; Nguyen-Xuan, H. Machine learning-based real-time daylight analysis in buildings. J. Build. Eng. 2022, 52, 104374. [Google Scholar]

- Zhang, J.; Huang, Y.; Cheng, H.; Chen, H.; Xing, L.; He, Y. Ensemble learning-based approach for residential building heating energy prediction and optimization. J. Build. Eng. 2023, 67, 106051. [Google Scholar] [CrossRef]

- Degtyarev, V.V.; Tsavdaridis, K.D. Buckling and ultimate load prediction models for perforated steel beams using machine learning algorithms. J. Build. Eng. 2022, 51, 104316. [Google Scholar] [CrossRef]

- Cheng, J.L.; Zhao, J.H.; Dong, Y.; Dong, Q.Y. Quantitative prediction of water abundance in rock mass by transient electro–magnetic method with LBA–BP neural network. J. China Coal Soc. 2020, 45, 330–337. [Google Scholar]

- Ma, D.; Bai, H. Groundwater inflow prediction model of karst collapse pillar: A case study for mining-induced groundwater inrush risk. Nat. Hazards 2015, 76, 1319–1334. [Google Scholar] [CrossRef]

- Wu, J.; Xu, S.; Zhou, R.; Qin, Y. Scenario analysis of mine water inrush hazard using Bayesian networks. Saf. Sci. 2016, 89, 231–239. [Google Scholar] [CrossRef]

- Qu, X.; Han, J.; Shi, L.; Qu, X.; Bilal, A.; Qiu, M.; Gao, W. An extended ITL-VIKOR model using triangular fuzzy numbers for applications to water-richness evaluation. Expert Syst. Appl. 2023, 222, 119793. [Google Scholar] [CrossRef]

- Mulumba, D.M.; Liu, J.; Hao, J.; Zheng, Y.; Liu, H. Application of an Optimized PSO-BP Neural Network to the Assessment and Prediction of Underground Coal Mine Safety Risk Factors. Appl. Sci. 2023, 13, 5317. [Google Scholar] [CrossRef]

- Gul, M.; Ak, M.F.; Guneri, A.F. Pythagorean fuzzy VIKOR-based approach for safety risk assessment in mine industry. J. Saf. Res. 2019, 69, 135–153. [Google Scholar] [CrossRef]

- Mishra, R.; Uotinen, L.; Rinne, M. A Bayesian network approach for geotechnical risk assessment in underground mines. J. South. Afr. Inst. Min. Met. 2021, 121, 287–294. [Google Scholar] [CrossRef]

- Wang, S.-S.; Song, B.-L. Application of fuzzy analytic hierarchy process in sandstone aquifer water yield property evaluation. Environ. Technol. Innov. 2021, 22, 101488. [Google Scholar] [CrossRef]

- Liu, W.; Zheng, Q.; Pang, L.; Dou, W.; Meng, X. Study of roof water inrush forecasting based on EM-FAHP two-factor model. Math. Biosci. Eng. 2021, 18, 4987–5005. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Bao, W.; Li, M. Comprehensive Water Inrush Risk Assessment Method for Coal Seam Roof. Sustainability 2022, 14, 10475. [Google Scholar] [CrossRef]

- Li, Z.; Liu, F.; Yang, W.; Peng, S.; Zhou, J. A Survey of Convolutional Neural Networks: Analysis, Applications, and Prospects. IEEE Trans. Neural Netw. Learn. Syst. 2022, 33, 6999–7019. [Google Scholar] [CrossRef]

- Sun, Y.; Xue, B.; Zhang, M.; Yen, G.G. Evolving Deep Convolutional Neural Networks for Image Classification. IEEE Trans. Evol. Comput. 2020, 24, 394–407. [Google Scholar] [CrossRef]

- Shao, H.; Xia, M.; Han, G.; Zhang, Y.; Wan, J. Intelligent Fault Diagnosis of Rotor-Bearing System Under Varying Working Conditions With Modified Transfer Convolutional Neural Network and Thermal Images. IEEE Trans. Ind. Inform. 2021, 17, 3488–3496. [Google Scholar] [CrossRef]

- Mittal, S. A survey of FPGA-based accelerators for convolutional neural networks. Neural Comput. Appl. 2020, 32, 1109–1139. [Google Scholar] [CrossRef]

- Khan, A.; Sohail, A.; Zahoora, U.; Qureshi, A.S. A survey of the recent architectures of deep convolutional neural networks. Artif. Intell. Rev. 2020, 53, 5455–5516. [Google Scholar] [CrossRef]

- Goumiri, S.; Benboudjema, D.; Pieczynski, W. A new hybrid model of convolutional neural networks and hidden Markov chains for image classification. Neural Comput. Appl. 2023, 35, 17987–18002. [Google Scholar] [CrossRef] [PubMed]

- Wan, Z.; Dong, Y.; Yu, Z.; Lv, H.; Lv, Z. Semi-Supervised Support Vector Machine for Digital Twins Based Brain Image Fusion. Front. Neurosci. 2021, 15, 705323. [Google Scholar] [CrossRef] [PubMed]

- Sheykhmousa, M.; Mahdianpari, M.; Ghanbari, H.; Mohammadimanesh, F.; Ghamisi, P.; Homayouni, S. Support Vector Machine Versus Random Forest for Remote Sensing Image Classification: A Meta-Analysis and Systematic Review. IEEE J. Sel. Top. Appl. Earth Obs. Remote. Sens. 2020, 13, 6308–6325. [Google Scholar] [CrossRef]

- Cholette, M.E.; Borghesani, P.; Di Gialleonardo, E.; Braghin, F. Using support vector machines for the computationally efficient identification of acceptable design parameters in computer-aided engineering applications. Expert Syst. Appl. 2017, 81, 39–52. [Google Scholar] [CrossRef]

- Zhao, R.; Yan, R.; Chen, Z.; Mao, K.; Wang, P.; Gao, R.X. Deep learning and its applications to machine health monitoring. Mech. Syst. Signal Process. 2019, 115, 213–237. [Google Scholar] [CrossRef]

- Sony, S.; Dunphy, K.; Sadhu, A.; Capretz, M. A systematic review of convolutional neural network-based structural condition assessment techniques. Eng. Struct. 2021, 226, 111347. [Google Scholar] [CrossRef]

- Shen, Z.; Zhang, Y.; Lu, J.; Xu, J.; Xiao, G. A novel time series forecasting model with deep learning. Neurocomputing 2020, 396, 302–313. [Google Scholar] [CrossRef]

- Alzubaidi, L.; Zhang, J.; Humaidi, A.J.; Al-Dujaili, A.; Duan, Y.; Al-Shamma, O.; Santamaría, J.; Fadhel, M.A.; Al-Amidie, M.; Farhan, L. Review of deep learning: Concepts, CNN architectures, challenges, applications, future directions. J. Big Data 2021, 8, 1–74. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. Commun. ACM 2017, 60, 84–90. [Google Scholar] [CrossRef]

- Cervantes, J.; Garcia-Lamont, F.; Rodriguez-Mazahua, L.; Lopez, A. A comprehensive survey on support vector machine clas-sification: Applications, challenges and trends. Neurocomputing 2020, 408, 189–215. [Google Scholar] [CrossRef]

- Mirjalili, S.; Lewis, A. The Whale Optimization Algorithm. Adv. Eng. Softw. 2016, 95, 51–67. [Google Scholar] [CrossRef]

- Gharehchopogh, F.S.; Gholizadeh, H. A comprehensive survey: Whale Optimization Algorithm and its applications. Swarm Evol. Comput. 2019, 48, 1–24. [Google Scholar] [CrossRef]

- Zhou, P.; Zhou, G.; Zhu, Z.; Tang, C.; He, Z.; Li, W.; Jiang, F. Health Monitoring for Balancing Tail Ropes of a Hoisting System Using a Convolutional Neural Network. Appl. Sci. 2018, 8, 1346. [Google Scholar] [CrossRef]

- Fan, D.; Sun, H.; Yao, J.; Zhang, K.; Yan, X.; Sun, Z. Well production forecasting based on ARIMA-LSTM model considering manual operations. Energy 2021, 220, 119708. [Google Scholar] [CrossRef]

- He, S.; Wu, J.; Wang, D.; He, X. Predictive modeling of groundwater nitrate pollution and evaluating its main impact factors using random forest. Chemosphere 2022, 290, 133388. [Google Scholar] [CrossRef]

- Huang, W.; Liu, H.; Zhang, Y.; Mi, R.; Tong, C.; Xiao, W.; Shuai, B. Railway dangerous goods transportation system risk identification: Comparisons among SVM, PSO-SVM, GA-SVM and GS-SVM. Appl. Soft Comput. 2021, 109, 107541. [Google Scholar] [CrossRef]

Figure 1.

Coal Mine Outline Diagram.

Figure 1.

Coal Mine Outline Diagram.

Figure 2.

Thematic map of indicators for water yield assessment: (a) Aquifer thickness; (b) Radius of influence; (c) Normalized drawdown; (d) Permeability coefficient; (e) Core recovery percentage; (f) Proportion of clay thickness to lower group thickness.

Figure 2.

Thematic map of indicators for water yield assessment: (a) Aquifer thickness; (b) Radius of influence; (c) Normalized drawdown; (d) Permeability coefficient; (e) Core recovery percentage; (f) Proportion of clay thickness to lower group thickness.

Figure 3.

Schematic diagram of CNN structure.

Figure 3.

Schematic diagram of CNN structure.

Figure 4.

Flowchart of CNN-SVM algorithm.

Figure 4.

Flowchart of CNN-SVM algorithm.

Figure 5.

Flowchart of WOA-CNN algorithm.

Figure 5.

Flowchart of WOA-CNN algorithm.

Figure 6.

Sample prediction process and results: (a) Loss curves; (b) Predicted versus true values of training samples; (c) Test sample predicted versus true values.

Figure 6.

Sample prediction process and results: (a) Loss curves; (b) Predicted versus true values of training samples; (c) Test sample predicted versus true values.

Figure 7.

Comparison of predicted and real values: (a) SVM; (b) CNN; (c) WOA-SVM; (d) WOA-CNN; (e) CNN-SVM; (f) WOA-CNN-SVM.

Figure 7.

Comparison of predicted and real values: (a) SVM; (b) CNN; (c) WOA-SVM; (d) WOA-CNN; (e) CNN-SVM; (f) WOA-CNN-SVM.

Figure 8.

Comparison of predictive performance of different models: (a) Optimized vs. unoptimized models; (b) Optimization model vs. other models.

Figure 8.

Comparison of predictive performance of different models: (a) Optimized vs. unoptimized models; (b) Optimization model vs. other models.

Figure 9.

Thematic map of water yield zoning in the study area: (a) Divided according to regulations; (b) Natural breakpoint method partitioning; (c) 3D surface map.

Figure 9.

Thematic map of water yield zoning in the study area: (a) Divided according to regulations; (b) Natural breakpoint method partitioning; (c) 3D surface map.

Table 1.

Water Yield Index Value.

Table 1.

Water Yield Index Value.

| Drill Hole Number | Dominant Factors | Unit Water Inflow Rate/ L·s−1·m−1 |

|||||

|---|---|---|---|---|---|---|---|

| X1/m | X2/m | X3/m | X4/m·d−1 | X5 | X6 | ||

| 1 | 29.00 | 23.61 | 3.63 | 0.42 | 0.62 | 0.43 | 0.05 |

| 2 | 23.61 | 5.00 | 51.78 | 0.03 | 0.76 | 0.48 | 0.00 |

| 3 | 13.35 | 66.47 | 11.52 | 0.90 | 0.55 | 0.39 | 0.12 |

| 4 | 35.10 | 93.16 | 6.32 | 0.50 | 0.82 | 0.12 | 0.09 |

| 5 | 22.80 | 10.12 | 51.98 | 0.00 | 0.74 | 0.49 | 0.00 |

| 6 | 23.10 | 79.04 | 10.00 | 0.75 | 0.80 | 0.41 | 0.10 |

| 7 | 19.35 | 82.03 | 10.00 | 0.76 | 0.61 | 0.60 | 0.08 |

| 8 | 11.70 | 75.84 | 15.26 | 0.53 | 1.00 | 0.17 | 0.15 |

| 9 | 23.75 | 39.01 | 1.68 | 2.02 | 0.36 | 0.55 | 0.19 |

| 10 | 35.10 | 61.12 | 17.58 | 0.49 | 0.71 | 0.38 | 0.09 |

| 11 | 24.35 | 701.35 | 114.77 | 1.90 | 0.54 | 0.10 | 0.08 |

| 12 | 21.40 | 184.69 | 10.00 | 2.02 | 1.00 | 0.55 | 0.19 |

| 13 | 28.34 | 68.12 | 7.09 | 0.88 | 0.62 | 0.50 | 0.06 |

| 14 | 43.10 | 153.01 | 1.04 | 0.39 | 1.00 | 0.46 | 0.20 |

| 15 | 22.80 | 98.49 | 10.36 | 0.90 | 0.71 | 0.20 | 0.09 |

| 16 | 28.94 | 6.49 | 27.27 | 0.39 | 0.70 | 0.23 | 0.00 |

| 17 | 23.80 | 18.94 | 2.66 | 0.63 | 0.73 | 0.26 | 0.16 |

| 18 | 23.80 | 49.44 | 10.00 | 0.48 | 0.65 | 0.51 | 0.07 |

| 19 | 5.30 | 99.88 | 51.78 | 0.04 | 0.42 | 0.29 | 0.00 |

| 20 | 18.11 | 126.40 | 9.80 | 1.63 | 0.78 | 0.39 | 0.10 |

| 21 | 21.45 | 116.86 | 0.95 | 8.51 | 0.35 | 0.35 | 0.00 |

| 22 | 19.26 | 21.16 | 17.40 | 0.56 | 0.41 | 0.08 | 0.12 |

| 23 | 10.35 | 25.94 | 1.40 | 0.76 | 0.41 | 0.51 | 0.08 |

| 24 | 29.00 | 64.97 | 5.02 | 1.78 | 0.59 | 0.19 | 0.18 |

| 25 | 21.45 | 28.58 | 0.95 | 8.51 | 0.69 | 0.29 | 0.63 |

| 26 | 20.06 | 85.13 | 7.29 | 0.58 | 0.78 | 0.45 | 0.02 |

| 27 | 8.85 | 45.19 | 11.16 | 0.51 | 0.52 | 0.57 | 0.05 |

| 28 | 23.11 | 75.06 | 8.03 | 0.75 | 0.49 | 0.18 | 0.10 |

| 29 | 28.71 | 37.29 | 1.78 | 2.14 | 0.50 | 0.52 | 0.46 |

| 30 | 11.22 | 137.15 | 10.00 | 1.78 | 1.00 | 0.17 | 0.18 |

| 31 | 30.45 | 1.15 | 10.00 | 1.15 | 0.74 | 0.31 | 0.54 |

| 32 | 36.41 | 58.63 | 5.52 | 0.53 | 0.82 | 0.36 | 0.14 |

| 33 | 5.30 | 70.97 | 51.78 | 0.04 | 0.87 | 0.49 | 0.00 |

| 34 | 27.40 | 66.47 | 27.27 | 0.06 | 0.53 | 0.47 | 0.00 |

| 35 | 25.15 | 297.87 | 46.87 | 1.90 | 0.35 | 0.36 | 0.08 |

| 36 | 36.41 | 96.61 | 26.72 | 0.54 | 0.49 | 0.29 | 0.12 |

| 37 | 20.42 | 118.71 | 6.05 | 1.72 | 0.46 | 0.19 | 0.02 |

| 38 | 29.00 | 75.03 | 3.63 | 0.42 | 0.57 | 0.23 | 0.01 |

| 39 | 20.05 | 223.85 | 14.40 | 1.42 | 0.65 | 0.59 | 0.04 |

| 40 | 28.23 | 40.13 | 7.04 | 0.312 | 0.82 | 0.28 | 0.06 |

Table 2.

Unit water inflow rate prediction results.

Table 2.

Unit water inflow rate prediction results.

| Drill Hole Number | Dominant Factors | Projected Results /L·s−1·m−1 |

|||||

|---|---|---|---|---|---|---|---|

| X1/m | X2/m | X3/m | X4/m·d−1 | X5 | X6 | ||

| 41 | 7.83 | 5.21 | 51.78 | 0.04 | 0.76 | 0.26 | 0.00 |

| 42 | 8.36 | 158.21 | 28.68 | 0.42 | 0.47 | 0.39 | 0.00 |

| 43 | 36.41 | 96.61 | 26.72 | 0.54 | 0.49 | 0.29 | 0.12 |

| 44 | 24.05 | 233.81 | 46.87 | 0.40 | 0.63 | 0.26 | 0.02 |

| 45 | 28.23 | 40.13 | 7.04 | 0.32 | 0.82 | 0.28 | 0.06 |

| 46 | 12.69 | 33.64 | 29.62 | 0.12 | 0.07 | 0.36 | 0.05 |

| 47 | 7.12 | 23.17 | 24.55 | 0.45 | 0.01 | 0.12 | 0.05 |

| 48 | 22.03 | 12.57 | 17.35 | 0.13 | 0.01 | 0.26 | 0.02 |

| 49 | 17.25 | 45.12 | 69.22 | 0.44 | 0.01 | 0.07 | 0.14 |

| 50 | 15.44 | 18.69 | 11.62 | 0.26 | 0.07 | 0.46 | 0.05 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

[ad_2]