An indicator is an assessment and decision-making parameter based on a set of measurable or assessable elements that can be used to describe the performance, state or impact of a system in figures. Efficiency () or mass and volume power densities are examples of such indicators. New indicators are necessary to qualify and quantify sustainability in the field of power electronics. Some of them are standardized and generic like the environmental impact indicators. Others are more specific to each field and support the evaluation and design process. They are defined hereafter as technological sustainability indicators.

4.2.1. Environmental Indicators: State-of-the-Art Analysis

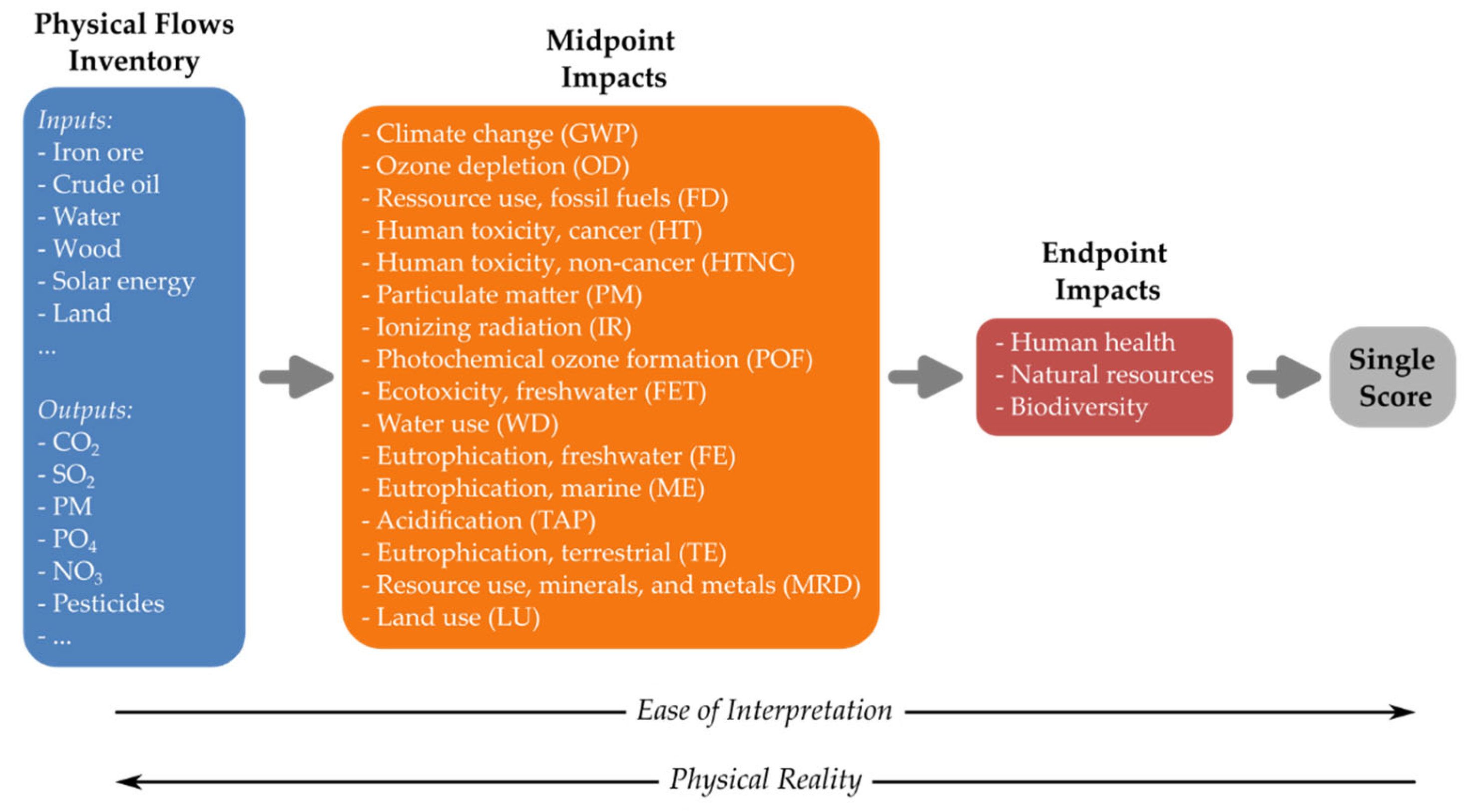

The environmental impact indicators are used in particular in LCA (Life Cycle Assessment). This method allows for the evaluation of the environmental impacts thanks to indicators computed on a defined scope for a system or product throughout its life cycle. Multiple indicators exist and they are classified by level as described in

Figure 6.

The physical flows identified during the Life Cycle Inventory (LCI) are used to compute the midpoint impacts that are shown in

Figure 6. Then, these impacts might be aggregated to compute the endpoint impacts that are related to the damages done to human health and the ecosystems. In a similar manner, these endpoint impacts might be aggregated to obtain a single score. The more aggregated the indicators, the easier and quicker it is for the stakeholders (manufacturers, users) to communicate and understand them. In exchange, the aggregation of indicators implies a loss of information on the physics of the environmental impacts of the product or system considered.

Considering the diversity of environmental indicators ensures that a global picture of the environmental impacts is obtained. Conversely, when only a subset of indicators is considered, for example,

emissions, rebound effects or impact transfer might occur. They result in a decrease in the effect of one given impact at the expense of an increase in the effect of another impact, which is neither desirable nor visible when using a single score or a limited number of indicators. In addition, interpretation difficulties arise due to the weighting used in the aggregation of several indicators into one single score. This is the reason why these weightings are subject to European recommendations which are adjusted each year and may also depend on the applications studied [

31].

Figure 6.

Environmental impact indicators—Compromise between physical reality and ease of interpretation.

Figure 6.

Environmental impact indicators—Compromise between physical reality and ease of interpretation.

Impact transfer and rebound effects are not only linked to a focus on too few indicators, they might also appear when only some parts of the entire life cycle are considered. Indeed, some environmental impacts might be low for the considered life cycle phases but great for the neglected phases. This can imply a serious discrepancy between the estimated environmental impacts and the real environmental impacts of the overall life cycle. This lack of a systemic approach has been pointed out several times in the literature in studies about the LCA of batteries [

32,

33] and solar panel systems [

34]. This lack is also due to other factors, such as the diversity of approaches, methods, software and/or data used, the lack of transparency regarding the Life Cycle Assessments carried out in the literature, the diversity of

goal and scope and/or applications considered. The consequences are significant difficulties in interpreting and/or comparing studies or difficulties in extracting general conclusions and/or recommendations.

In the field of power electronics, a number of studies have assessed the environmental impacts of power converters [

16,

17,

24,

35,

36,

37]. It should be noted; however, that with the exception of [

24], which deals with a complete LCA of a 150 kW traction inverter, most of the research focuses mainly on single score energy or

emission balances, which is not in line with the systemic approach previously mentioned.

These environmental impact indicators are necessary to design more sustainable power electronics converters, but they are not sufficient. These indicators are not suitable for decisions made early in the design process by the power electronics researcher or designer. This is why the development of new indicators is necessary.

4.2.2. Development of Technological Sustainability Indicators for Power Electronics

In addition to the previously mentioned environmental impact indicators, it is important to complete state-of-the-art analysis with the Technological Sustainability Indicators. First, the indicators specifically developed in the literature towards sustainability in the field of power electronics are presented, and then those developed for electrical engineering in general are detailed. Next, a proposed approach for developing new technological sustainability indicators is put forward.

Power efficiency is one of the most used indicators for the design of power electronics. This indicator considers only the use phase of the life cycle of the converters. Therefore, it is not sufficient to assess the environmental impact of a converter. Another very popular indicator is the mass power density, which is indirectly part of the mass of raw material used in the manufacture phase of the life cycle of the converter. These two indicators are only a very partial response to the need to assess sustainability in power electronics, as they cover only part of the life cycle and consider only a few environmental indicators.

Recently more systemic indicators have been designed for electrical engineering. The

Life Cycle efficiency, developed in [

37], considers the energy flows of all life cycle phases of the converter. It is defined as:

With

the delivered energy during the use phase of the converter,

the energy due to its losses during the use phase,

the energy used during its manufacturing phase and

the energy used during its End-of-Life (EoL) treatment. Other indicators like the

residual value [

38], and the

embodied energy [

39] includes also several phases of the life cycle. All these indicators are intended to support the decision-making process considering the various product phases (design, manufacture, use, circularity scenario, and end-of-life management).

Some indicators have been specifically developed for production systems like the

Carbon and

Energy Payback Periods [

30,

40]. The

Health Index for Power Transformers [

41] might also be used as inspiration for new indicators.

A complete and more sorted inventory of indicators, together with their descriptions, is available in [

7] (this document is provided as is for research purposes and does not constitute a recommendation by the workgroup CEPPS).

Various indicators could be developed over the next few years to respond specifically to sustainability needs in the field of power electronics. While these technological indicators represent a major challenge for the power electronics community, it is important to link them to a systemic approach (covering the entire life cycle). They should complement the environmental impact indicators (used to quantify the impacts of the studied device), and they should help with the design and development of more sustainable power converters as depicted in

Figure 7.

There are many different types of indicators, some of which already exist, to develop or to improve for several design criteria like reliability [

42], ease of disassembly [

43], repairability [

42,

44], reuse, complexity and indicators. For example, the French repairability index is a decision-making tool for consumers, rather than for product designers. In addition, the use of a weighted sum may, in some cases, create bias, and therefore calls for an improvement in this indicator for designers [

44].

The failure rate from the field of reliability is another example of an already existing indicator that can be incorporated into converter sustainability studies, in particular, to estimate the lifetime or the residual value at the end of usage.

Finally, the last European recommendations on eco-design include more and more electrical systems (motors and transformers). This augurs well for the arrival of new regulations and a market for the circularity of electrical equipment including power electronics, which underlines the importance of using indicators that are both understandable and relevant for the power electronics designer.