Application of Virtual Reality (VR) Technology in Mining and Civil Engineering

[ad_1]

1. Introduction

Technological progress is an important criterion for global economic development. Innovative technologies used by companies often determine their profitability and efficiency but are also an important element of an innovative and attractive workplace. Today, the most advanced technologies are based on the automation and robotisation of processes using drones, inspection robots, exoskeletons or virtual reality (VR). This last technology is a particular area of research for many scientists around the world. In recent years, there have been significant technological advances that have given engineers access to different tools for modelling and visualising different parts of our reality.

Virtual reality has seen significant progress since its modest beginnings in the 1990s. Initially experimental and confined to research laboratories and academic institutions, the technology has shown an evolution in both hardware and software, leading to advanced VR systems. In the first decade of the 21st century, the technological boom brought the emergence of VR pioneers, ushering in a new era of virtual reality exploration. The increased interest in this area has led to the development of a number of platforms offering high-quality visual experiences, interactions and immersive experiences for users.

Innovations in interaction have played a key role in the technological development of VR. The introduction of wired or wireless motion controllers has enabled users to manipulate objects in a virtual environment, further increasing immersion and engagement. In addition, motion-tracking technologies have made it possible to move more naturally in a virtual space, increasing the realism of the experience.

With the development of technology, VR has crossed the boundaries of entertainment and found its way into various fields such as education, training, medicine, architecture and tourism. The ability to move into a virtual environment allows users to experience reality in a completely new way, opening the door to unlimited possibilities for exploration and creation.

Virtual reality has come a considerable way from its modest beginnings to the now sophisticated systems that offer users the opportunity to embody entirely new worlds and experience reality in ways that seemed impossible just a few years ago.

Virtual reality (VR) technology has emerged as a transformative tool with the potential to significantly enhance sustainability in the realm of occupational health and safety (OHS), particularly within industries prone to high accident rates, such as mining and construction. The integration of VR technology into OHS practices represents a significant opportunity to enhance sustainability in industries with high accident rates. By improving safety practices, enhancing efficiency, minimising the environmental impact, enabling remote collaboration and driving innovation, VR contributes to fostering a safer, more sustainable workplace for current and future generations.

2. Virtual Reality

Many companies are looking for solutions to improve safety or ergonomics in new applications. This is particularly important in high-risk industries such as mining and construction. These industries have some of the highest accident rates and therefore require increased attention. The mining industry focuses on underground, surface and borehole mining. There are a number of hazards in each of these, and among the most dangerous are natural hazards, which often lead to serious and fatal accidents. The same applies to the construction industry, whose main activity is the execution of construction projects. In this industry, the main hazards are working at height and contact with heavy structural elements. Again, there is a high probability of serious and fatal accidents.

3. Materials and Methods

4. Application of Virtual Reality (VR) Technology in Mining and Civil Engineering

4.1. Mining

4.1.1. Education

4.1.2. Design, Simulation and Monitoring of Technological Processes

4.1.3. Occupational Safety

4.2. Construction

4.2.1. Education

Technological innovations such as virtual reality (VR) have been successfully integrated into education and training programs. A number of simulated virtual environments have been developed, improving learning outcomes for their participants, improving the ability to acquire knowledge, including specialised knowledge in the workplace, which, using traditional methods, requires years of experience and apprenticeship training.

VR technology makes it possible to simulate various construction environments and processes, analyse the correctness of accepted schemes and modify functional parameters, which enables the optimisation of the planning, design and construction processes of a construction project. Virtual reality offers immersive learning opportunities and a cost-effective solution in an immersive and safe environment for construction safety training.

4.2.2. Design, Simulation and Monitoring of Technological Processes

Construction planning is a complex activity that involves extracting construction activities from project documentation to drawings, allocating human and equipment resources on site, planning a safe workplace for construction workers and planning the sequence of activities.

4.2.3. Occupational Safety

Construction is a high-risk industry with a high accident rate, and the main contributor to construction accidents is the human factor. Many workers lack sufficient safety and health training, resulting in a deficit of knowledge and skills. It is imperative to implement effective training programs to enhance workers’ safety competence and mitigate accidents. Relying on firsthand experience to learn about hazardous situations is legally and ethically unfeasible and unjustifiable. A potential solution to address this issue is through virtual reality (VR) simulations, which afford trainees and employees the opportunity to safely experience dangerous scenarios without exposing them to real-world hazards. Virtual reality-assisted training is gaining importance due to its immersive nature and high involvement of trainees, which is lacking in traditional lecture-based safety training.

5. Future of VR Technology—Discussion

The potential in this technology has also been recognised by the industry, which is proving that virtual reality can be successfully used in the design of construction and mining facilities, but also machinery, significantly reducing the associated costs. VR technology makes it possible to create simulation models, so you can see exactly what the finished project will look like before production and commissioning. Virtual reality design also allows you to make changes to models immediately, without having to physically rebuild them.

Based on the observations of the authors, as well as the analysis of scientific achievements, it is possible to characterise the general directions of the development and use of virtual reality accordingly:

- –

-

The pervasiveness of VR technology for research and business management;

- –

-

Creation of digital training rooms and classrooms that will allow one to experience phenomena and events that are reflected in reality;

- –

-

Creation of virtual models and scenarios that allow simultaneous use by multiple operators (multiplayer);

- –

-

Striving for a more realistic picture of the virtual environment;

- –

-

Ongoing (online) planning and creation of models and scenarios, active visualisation and simulation of phenomena and events allowing one to observe production processes with variable parameters.

6. Conclusions

Virtual reality has great potential, but its implementation is not yet mature. VR technology has gained great recognition in the mining and construction industry. It is widely used at every stage of operations, taking into account the design, planning and management processes and the creation of safe working conditions. It is possible that, in the near future, it will be an important tool not only for optimising technological processes, costs and profits in the world’s most profitable companies but also for shaping the better achievements of mankind. Given the uninterrupted technological and scientific development, it can also be concluded that VR will be one of the key elements in the development of expansion beyond our planet.

This study adds to the literature by identifying past and present research areas related to the application of virtual reality. The integration of the technology into the sectors discussed has a very positive vision for the future, and the sub-areas presented have great potential for the application of the technology.

Author Contributions

Conceptualisation, P.S. and M.S.; methodology, P.S.; validation, P.S., P.B., M.S. and M.N.; formal analysis, P.S., P.B., M.S. and M.N.; investigation, P.S., P.B., M.S. and M.N.; writing—original draft preparation, P.S., P.B., M.S. and M.N.; writing—review and editing, P.S., P.B., M.S. and M.N.; supervision, P.S. and M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the Polish Ministry of Education and Science Subsidy 2023 for the Department of Mining WUST (grant number 8211104160).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bellanca, J.L.; Orr, T.J.; Helfrich, W.J.; Macdonald, B.; Navoyski, J.; Demich, B. Developing a Virtual Reality Environment for Mining Research. Min. Metall. Explor. 2019, 36, 597–606. [Google Scholar] [CrossRef] [PubMed]

- Christiansson, P. Dynamic Knowledge Nets in a Changing Building Process. Autom. Constr. 1993, 1, 307–322. [Google Scholar] [CrossRef]

- Hui, Z. Head-mounted display-based intuitive virtual reality training system for the mining industry. Int. J. Min. Sci. Technol. 2017, 27, 717–722. [Google Scholar] [CrossRef]

- Stothard, P.; Laurence, D. Application of a Large-Screen Immersive Visualisation System to Demonstrate Sustainable Mining Practices Principles. Min. Technol. 2014, 123, 199–206. [Google Scholar] [CrossRef]

- Pedram, S.; Palmisano, S.; Miellet, S.; Farrelly, M.; Perez, P. Influence of Age and Industry Experience on Learning Experiences and Outcomes in Virtual Reality Mines Rescue Training. Front. Virtual Real. 2022, 3, 941225. [Google Scholar] [CrossRef]

- Kim, H.; Choi, Y. Performance Comparison of User Interface Devices for Controlling Mining Software in Virtual Reality Environments. Appl. Sci. 2019, 9, 2584. [Google Scholar] [CrossRef]

- Assfalg, J.; Del Bimbo, A.; Vicario, E. Using 3D and Ancillary Media to Train Construction Workers. IEEE Multimed. 2002, 9, 88–92. [Google Scholar] [CrossRef]

- Stothard, P.; Squelch, A.; Stone, R.; Van Wyk, E. Towards Sustainable Mixed Reality Simulation for the Mining Industry. Min. Technol. 2019, 128, 246–254. [Google Scholar] [CrossRef]

- Radianti, J.; Majchrzak, T.; Fromm, K.; Wohlgenannt, I. A systematic review of immersive virtual reality applications for higher education: Design elements, lessons learned, and research agenda. Comput. Educ. 2000, 147, 103778. [Google Scholar] [CrossRef]

- Hamad, A.; Jia, B. How Virtual Reality Technology Has Changed Our Lives: An Overview of the Current and Potential Applications and Limitations. Int. J. Nviron Res. Public Helath 2022, 19, 11278. [Google Scholar] [CrossRef]

- Babalola, A.; Manu, P.; Cheung, C.; Yunusa-Kaltungo, A.; Bartolo, P. Applications of Immersive Technologies for Occupational Safety and Health Training and Education: A Systematic Review. Saf. Sci. 2023, 166, 106214. [Google Scholar] [CrossRef]

- Strojny, P.; Dużmańska-Misiarczyk, N. Measuring the effectiveness of virtual training: A systematic review. Comput. Educ. X Real. 2023, 2, 100006. [Google Scholar] [CrossRef]

- Mitra, R.; Saydam, S. Using Virtual Reality In Tertiary Education. Int. J. Technol. Learn. 2013, 19, 97–112. [Google Scholar] [CrossRef]

- Dorey, F.; Knights, P.F. Quantifying the Benefits of Simulator Training for Dragline Operators. Min. Technol. 2015, 124, 97–106. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, L.; Qi, X.; Geng, J. Digital Mining Technology-Based Teaching Mode for Mining Engineering. Int. J. Emerg. Technol. Learn. IJET 2016, 11, 47. [Google Scholar] [CrossRef]

- Xie, J.; Yang, Z.; Wang, X.; Wang, Y. A Remote VR Operation System for a Fully Mechanised Coal-Mining Face Using Real-Time Data and Collaborative Network Technology. Min. Technol. 2018, 127, 230–240. [Google Scholar] [CrossRef]

- Xie, J.; Yang, Z.; Wang, X.; Zeng, Q.; Li, J.; Li, B. A Virtual Reality Collaborative Planning Simulator and Its Method for Three Machines in a Fully Mechanized Coal Mining Face. Arab. J. Sci. Eng. 2018, 43, 4835–4854. [Google Scholar] [CrossRef]

- Chou, C.; Hsu, H.; Yu-Seng, Y. Construction of a Virtual Reality Learning Environment for Teaching Structural Analysis. Comput. Appl. Eng. Educ. 1998, 5, 223–239. [Google Scholar] [CrossRef]

- Walker, J.; Towey, D.; Pike, M.; Kapogiannis, G.; Elamin, A.; Wei, R. Developing a Pedagogical Photoreal Virtual Environment to Teach Civil Engineering. Interact. Technol. Smart Educ. 2020, 17, 303–321. [Google Scholar] [CrossRef]

- Wilkins, B.; Barrett, J. The Virtual Construction Site: A Web-Based Teaching/Learning Environment in Construction Technology. Autom. Constr. 2000, 10, 169–179. [Google Scholar] [CrossRef]

- Budhu, M. Enhancing Instructions Using Interactive Multimedia Simulations. Simulation 2001, 76, 222–231. [Google Scholar] [CrossRef]

- Souza, P.C.; Rosatelli, M.C.; Wazlawick, R.S. A Collaborative Virtual Environment for Problem Solving in Civil Engineering. Int. J. Contin. Eng. Educ. Life Long. Learn. 2002, 12, 472–484. [Google Scholar] [CrossRef]

- Sampaio, A.Z.; Henriques, P.G.; Studer, P. Learning Construction Processes Using Virtual Reality Models. Electron. J. Inf. Technol. Constr. 2005, 10, 141–151. [Google Scholar]

- Sampaio, A.Z.; Henriques, P.G.; Studer, P. Computer-Aided System in Construction Process Based on Virtual Reality Technology. Int. J. Hous. Sci. Its Appl. 2004, 28, 109–119. [Google Scholar]

- Sampaio, A.Z.; Henriques, P.G.; Studer, P. Virtual Reality Technology Applied to Simulate Construction Processes. In Proceedings of the International Conference on Computational Science and Its Applications, Assisi, Italy, 14–17 May 2004; pp. 817–826. [Google Scholar] [CrossRef]

- Setareh, M.; Bowman, D.A.; Kalita, A.; Gracey, M.; Lucas, J. Application of a Virtual Environment System in Building Sciences Education. J. Archit. Eng. 2005, 11, 165–172. [Google Scholar] [CrossRef]

- Miyamoto, A.; Konno, M.-A.; Rissanen, T. VR-Based Education System for Inspection of Concrete Bridges. Comput. Concr. 2006, 3, 29–42. [Google Scholar] [CrossRef]

- Wang, X.; Dunston, P.S. Design, Strategies, and Issues towards an Augmented Reality-Based Construction Training Platform. Electron. J. Inf. Technol. Constr. 2007, 12, 363–380. [Google Scholar]

- Vergara, D.; Rubio, M.P.; Lorenzo, M. New Approach for the Teaching of Concrete Compression Tests in Large Groups of Engineering Students. J. Prof. Issues Eng. Educ. Pract. 2017, 143, 05016009. [Google Scholar] [CrossRef]

- Jason, L. Immersive VR in the Construction Classroom to Increase Student Understanding of Sequence, Assembly, and Space of Wood Frame Construction. J. Inf. Technol. Constr. 2018, 23, 179–194. [Google Scholar]

- Vahdatikhaki, F.; El Ammari, K.; Langroodi, A.K.; Miller, S.; Hammad, A.; Doree, A. Beyond Data Visualization: A Context-Realistic Construction Equipment Training Simulators. Autom. Constr. 2019, 106, 102853. [Google Scholar] [CrossRef]

- Ito, M.; Funahara, Y.; Saiki, S.; Yamazaki, Y.; Kurita, Y. Development of a Cross-Platform Cockpit for Simulated and Tele-Operated Excavators. J. Robot. Mechatron. 2019, 31, 231–239. [Google Scholar] [CrossRef]

- Pooladvand, S.; Taghaddos, H.; Eslami, A.; Nekouvaght Tak, A.; Hermann, U. Evaluating Mobile Crane Lift Operations Using an Interactive Virtual Reality System. J. Constr. Eng. Manag. 2021, 147, 04021154. [Google Scholar] [CrossRef]

- Osti, F.; de Amicis, R.; Sanchez, C.A.; Tilt, A.B.; Prather, E.; Liverani, A. A VR Training System for Learning and Skills Development for Construction Workers. Virtual Real. 2021, 25, 523–538. [Google Scholar] [CrossRef]

- Guzsvinecz, T.; Orbán-Mihálykó, É.; Perge, E.; Sik-Lányi, C. The Effect of Engineering Education, on Spatial Ability, in Virtual Environments. Acta Polytech. Hung. 2023, 20, 11–30. [Google Scholar] [CrossRef]

- Fernández, A.; Muñoz-La Rivera, F.; Mora-Serrano, J. Virtual Reality Training for Occupational Risk Prevention: Application Case in Geotechnical Drilling Works. Int. J. Comput. Methods Exp. Meas. 2023, 11, 55–63. [Google Scholar] [CrossRef]

- Du, W.; Sepasgozar, S.M.E.; Khan, A.; Shirowzhan, S.; Garzon Romero, J. Developing an Interactive Pile Training Module for Construction Risk Management and Gaging Users’ Intentions. Constr. Innov. 2023. [Google Scholar] [CrossRef]

- Chakraborty, P.; Bise, C.J. A Virtual-Reality-Based Model For Task-Training of Equipment Operators In The Mining Industry. Miner. Resour. Eng. 2000, 9, 437–449. [Google Scholar] [CrossRef]

- Squelch, A. Virtual Reality for Mine Safety Training in South Africa. J. South. Afr. Inst. Min. Metall. 2001, 101, 209–216. [Google Scholar]

- Lucas, J.; Thabet, W.; Worlikar, P. A VR-Based Training Program for Conveyor Belt Safety. J. Inf. Technol. Constr. 2008, 13, 381–407. [Google Scholar]

- Schaum, A.; Nieto, A.; Karmis, M.; Schafrik, S.J. Haul Truck Safety and Virtual Environments Training. Min. Eng. 2008, 60, 56–60. [Google Scholar]

- Orr, T.; Mallett, L.; Margolis, K. Enhanced Fire Escape Training for Mine Workers Using Virtual Reality Simulation. Min. Eng. 2009, 61, 41–44. [Google Scholar]

- Cai, L.; Cen, M.; Luo, Z.; Li, H. Modeling Risk Behaviors in Virtual Environment Based on Multi-Agent. In Proceedings of the 2010 the 2nd International Conference on Computer and Automation Engineering (ICCAE), Singapore, 26–28 February 2010; pp. 445–448. [Google Scholar] [CrossRef]

- Cai, L.X.; Yang, S.; Qu, H.; Yang, Z. Modeling and Simulating Risk Behaviors in Virtual Mine Based on Multi-Agent. J. Comput. Inf. Syst. 2011, 7, 523–530. [Google Scholar]

- Cai, L.; Yang, Z.; Yang, S.X.; Qu, H. Modelling and Simulating of Risk Behaviours in Virtual Environments Based on Multi-Agent and Fuzzy Logic. Int. J. Adv. Robot. Syst. 2013, 10, 387. [Google Scholar] [CrossRef]

- Podgórski, D. The Use of Tacit Knowledge in Occupational Safety and Health Management Systems. Int. J. Occup. Saf. Ergon. 2010, 16, 283–310. [Google Scholar] [CrossRef] [PubMed]

- Dickey, J.; Eger, T.; Frayne, R.; Delgado, G.; Ji, X. Research Using Virtual Reality: Mobile Machinery Safety in the 21st Century. Minerals 2013, 3, 145–164. [Google Scholar] [CrossRef]

- Webber-Youngman, R.C.W.; van Wyk, E.A. Incident Reconstruction Simulations-Potential Impact on the Prevention of Future Mine Incidents. J. South. Afr. Inst. Min. Metall. 2013, 113, 519–528. [Google Scholar]

- Lei, B.; Wu, B.; Zhou, Y. Coal Mine Emergency Rescue Drill System Based on Virtual Reality Technology. J. Chem. Pharm. Res. 2014, 6, 594–602. [Google Scholar]

- Grabowski, A.; Jankowski, J. Virtual Reality-Based Pilot Training for Underground Coal Miners. Saf. Sci. 2015, 72, 310–314. [Google Scholar] [CrossRef]

- Tan, B.; Zhang, Z.; Qin, X. Coal and Gas Outburst Accident Virtual Escape System for Miners Based on Virtools. Open Autom. Control Syst. J. 2015, 7, 379–385. [Google Scholar] [CrossRef]

- Liang, Z.; Zhou, K.; Gao, K. Development of Virtual Reality Serious Game for Underground Rock-Related Hazards Safety Training. IEEE Access 2019, 7, 118639–118649. [Google Scholar] [CrossRef]

- Gauthier, S.; Leduc, M.; Perfetto, S.J.; Godwin, A. Use of Virtual Reality to Increase Awareness of Line-of-Sight Hazards around Industrial Equipment. Safety 2022, 8, 52. [Google Scholar] [CrossRef]

- Gürer, S.; Surer, E.; Erkayaoğlu, M. Mining-Virtual: A Comprehensive Virtual Reality-Based Serious Game for Occupational Health and Safety Training in Underground Mines. Saf. Sci. 2023, 166, 106226. [Google Scholar] [CrossRef]

- Soedarmono, D.R.; Hadipriono, F.C.; Larew, R.E. Using Virtual Reality to Avoid Construction Falls. In Computing in Civil Engineering; ASCE: Reston, VA, USA, 1996; pp. 899–905. [Google Scholar]

- Hsiao, H.; Simeonov, P.; Dotson, B.; Ammons, D.; Kau, T.-Y.; Chiou, S. Human Responses to Augmented Virtual Scaffolding Models. Ergonomics 2005, 48, 1223–1242. [Google Scholar] [CrossRef] [PubMed]

- Rwamamara, R.; Norberg, H.; Olofsson, T.; Lagerqvist, O. Using Visualization Technologies for Design and Planning of a Healthy Construction Workplace. Constr. Innov. 2010, 10, 248–266. [Google Scholar] [CrossRef]

- Guo, H.; Li, H.; Chan, G.; Skitmore, M. Using Game Technologies to Improve the Safety of Construction Plant Operations. Accid. Anal. Prev. 2012, 48, 204–213. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Chan, G.; Skitmore, M. Multiuser Virtual Safety Training System for Tower Crane Dismantlement. J. Comput. Civ. Eng. 2012, 26, 638–647. [Google Scholar] [CrossRef]

- Le, Q.T.; Pedro, A.; Park, C.S. A Social Virtual Reality Based Construction Safety Education System for Experiential Learning. J. Intell. Robot. Syst. 2015, 79, 487–506. [Google Scholar] [CrossRef]

- Lu, X.; Davis, S. How Sounds Influence User Safety Decisions in a Virtual Construction Simulator. Saf. Sci. 2016, 86, 184–194. [Google Scholar] [CrossRef]

- Eiris, R.; Gheisari, M.; Esmaeili, B. PARS: Using Augmented 360-Degree Panoramas of Reality for Construction Safety Training. Int. J. Environ. Res. Public Health 2018, 15, 2452. [Google Scholar] [CrossRef]

- Nykänen, M.; Puro, V.; Tiikkaja, M.; Kannisto, H.; Lantto, E.; Simpura, F.; Uusitalo, J.; Lukander, K.; Räsänen, T.; Heikkilä, T.; et al. Implementing and Evaluating Novel Safety Training Methods for Construction Sector Workers: Results of a Randomized Controlled Trial. J. Saf. Res. 2020, 75, 205–221. [Google Scholar] [CrossRef]

- Eiris, R.; Jain, A.; Gheisari, M.; Wehle, A. Safety Immersive Storytelling Using Narrated 360-Degree Panoramas: A Fall Hazard Training within the Electrical Trade Context. Saf. Sci. 2020, 127, 104703. [Google Scholar] [CrossRef]

- Jelonek, M.; Fiala, E.; Herrmann, T.; Teizer, J.; Embers, S.; König, M.; Mathis, A. Evaluating Virtual Reality Simulations for Construction Safety Training. i-com 2022, 21, 269–281. [Google Scholar] [CrossRef]

- Yoo, J.W.; Park, J.S.; Park, H.J. Understanding VR-Based Construction Safety Training Effectiveness: The Role of Telepresence, Risk Perception, and Training Satisfaction. Appl. Sci. 2023, 13, 1135. [Google Scholar] [CrossRef]

- Rey-Becerra, E.; Barrero, L.H.; Ellegast, R.; Kluge, A. Improvement of Short-Term Outcomes with VR-Based Safety Training for Work at Heights. Appl. Erg. 2023, 112, 104077. [Google Scholar] [CrossRef] [PubMed]

- Rokooei, S.; Shojaei, A.; Alvanchi, A.; Azad, R.; Didehvar, N. Virtual Reality Application for Construction Safety Training. Saf. Sci. 2023, 157, 105925. [Google Scholar] [CrossRef]

- Feng, Z.; Lovreglio, R.; Yiu, T.W.; Acosta, D.M.; Sun, B.; Li, N. Immersive Virtual Reality Training for Excavation Safety and Hazard Identification. Smart Sustain. Built Environ. 2023. [Google Scholar] [CrossRef]

- Alzarrad, A.; Miller, M.; Chowdhury, S.; McIntosh, J.; Perry, T.; Shen, R. Harnessing Virtual Reality to Mitigate Heat-Related Injuries in Construction Projects. CivilEng 2023, 4, 1157–1168. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, X.; Soole, P. Reconstruction and Simulation of 3D Open Pits: A Critical Path Towards Practical Virtual Mine. Miner. Resour. Eng. 1998, 7, 221–231. [Google Scholar] [CrossRef]

- Russ, K.; Wetherelt, A. Large-Scale Mine Visualization Using VRML. IEEE Comput. Graph. Appl. 1999, 19, 39–44. [Google Scholar] [CrossRef]

- Pinto, V.; Font, X.; Salgot, M.; Tapias, J.C.; Mañá, T. Using 3-D Structures and Their Virtual Representation as a Tool for Restoring Opencast Mines and Quarries. Eng. Geol. 2002, 63, 121–129. [Google Scholar] [CrossRef]

- Foster, P.J.; Burton, A. Modelling Potential Sightline Improvements to Underground Mining Vehicles Using Virtual Reality. Min. Technol. 2006, 115, 85–90. [Google Scholar] [CrossRef]

- Zhang, R.; Yu, D.; Li, X.; Yao, X.; Liu, Y. Surface Mine System Simulation and Safety Risk Management. J. China Univ. Min. Technol. 2006, 16, 413–415. [Google Scholar] [CrossRef]

- Valdés, J.J.; Barton, A.J. Multi-Objective Evolutionary Optimization for Constructing Neural Networks for Virtual Reality Visual Data Mining: Application to Geophysical Prospecting. Neural Netw. 2007, 20, 498–508. [Google Scholar] [CrossRef] [PubMed]

- Toraño, J.; Diego, I.; Menéndez, M.; Gent, M. A Finite Element Method (FEM)–Fuzzy Logic (Soft Computing)–Virtual Reality Model Approach in a Coalface Longwall Mining Simulation. Autom. Constr. 2008, 17, 413–424. [Google Scholar] [CrossRef]

- Wu, Q.; Xu, H.; Zhou, W. Development of a 3D GIS and Its Application to Karst Areas. Environ. Geol. 2008, 54, 1037–1045. [Google Scholar] [CrossRef]

- Zhang, S.X. Augmented Reality on Longwall Face for Unmanned Mining. Appl. Mech. Mater. 2010, 40–41, 388–391. [Google Scholar] [CrossRef]

- Kang, X.; Peng, Q. Integration of CAD Models with Product Assembly Planning in a Web-Based 3D Visualized Environment. Int. J. Interact. Des. Manuf. (IJIDeM) 2014, 8, 121–131. [Google Scholar] [CrossRef]

- Al-Fugara, A.; Al-Adamat, R.; Al-Kouri, O.; Taher, S. DSM Derived Stereo Pair Photogrammetry: Multitemporal Morphometric Analysis of a Quarry in Karst Terrain. Egypt. J. Remote Sens. Space Sci. 2016, 19, 61–72. [Google Scholar] [CrossRef]

- Aromaa, S.; Väänänen, K. Suitability of Virtual Prototypes to Support Human Factors/Ergonomics Evaluation during the Design. Appl. Erg. 2016, 56, 11–18. [Google Scholar] [CrossRef]

- Hou, S.; Meng, X.; Zhang, Y. Dynamic Generation Method of Virtual Coal Mining Scene Based on 3D Entities Transformation and Combination. Int. J. Multimed. Ubiquitous Eng. 2016, 11, 223–234. [Google Scholar] [CrossRef]

- van Wyk, E.A.; de Villiers, M.R. An Evaluation Framework for Virtual Reality Safety Training Systems in the South African Mining Industry. J. South. Afr. Inst. Min. Metall. 2019, 119, 427–436. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, Y. Analysis of the Rock Stratum in a Mining Area in China with Virtual Reality Technology. Geotech. Res. 2019, 6, 288–293. [Google Scholar] [CrossRef]

- Antoniou, V.; Bonali, F.L.; Nomikou, P.; Tibaldi, A.; Melissinos, P.; Mariotto, F.P.; Vitello, F.R.; Krokos, M.; Whitworth, M. Integrating Virtual Reality and GIS Tools for Geological Mapping, Data Collection and Analysis: An Example from the Metaxa Mine, Santorini (Greece). Appl. Sci. 2020, 10, 8317. [Google Scholar] [CrossRef]

- Li, J.; Liu, Y.; Xie, J.; Wang, X.; Ge, X. Cutting Path Planning Technology of Shearer Based on Virtual Reality. Appl. Sci. 2020, 10, 771. [Google Scholar] [CrossRef]

- Zuo, H. The Construction of Stratigraphic Structure Model in Mining Area under Virtual Reality–Geographic Information System. Arab. J. Geosci. 2020, 13, 853. [Google Scholar] [CrossRef]

- Rozmus, M.; Tokarczyk, J.; Michalak, D.; Dudek, M.; Szewerda, K.; Rotkegel, M.; Lamot, A.; Rošer, J. Application of 3D Scanning, Computer Simulations and Virtual Reality in the Redesigning Process of Selected Areas of Underground Transportation Routes in Coal Mining Industry. Energies 2021, 14, 2589. [Google Scholar] [CrossRef]

- Liu, K.; Chen, L.; Li, L.; Ren, H.; Wang, F.-Y. MetaMining: Mining in the Metaverse. IEEE Trans. Syst. Man. Cybern. Syst. 2023, 53, 3858–3867. [Google Scholar] [CrossRef]

- Goldstein, H. Is Virtual Reality for Real? Civ. Eng. 1995, 65, 45–48. [Google Scholar]

- Retik, A.; Shapira, A. VR-Based Planning of Construction Site Activities. Autom. Constr. 1999, 8, 671–680. [Google Scholar] [CrossRef]

- Tawfik, H.; Fernando, T. A Simulation Environment for Construction Site Planning. In Proceedings of the Fifth International Conference on Information Visualisation, London, UK, 25–27 July 2001; pp. 199–204. [Google Scholar] [CrossRef]

- Rojas, E.M.; Mukherjee, A. Modeling the Construction Management Process to Support Situational Simulations. J. Comput. Civ. Eng. 2003, 17, 273–280. [Google Scholar] [CrossRef]

- Savioja, L.; Mantere, M.; Olli, I.; Äyräväinen, S.; Gröhn, M.; Iso-Aho, J. Utilizing Virtual Environments in Construction Projects. Electron. J. Inf. Technol. Constr. 2003, 8, 85–99. [Google Scholar]

- Waly, A.F.; Thabet, W.Y. A Virtual Construction Environment for Preconstruction Planning. Autom. Constr. 2003, 12, 139–154. [Google Scholar] [CrossRef]

- Beucke, K.; Bürklin, B.; Hanff, J.; Schaper, D. Applications of Virtual Design and Construction in the Building Industry. Struct. Eng. Int. 2005, 15, 129–134. [Google Scholar] [CrossRef]

- Hammad, A.; Wang, H.; Mudur, S.P. Distributed Augmented Reality for Visualizing Collaborative Construction Tasks. J. Comput. Civ. Eng. 2009, 23, 418–427. [Google Scholar] [CrossRef]

- Xie, H.; Shi, W.; Issa, R.R.A. Using Rfid and Real-Time Virtual Reality Simulation for Optimization in Steel Construction. Electron. J. Inf. Technol. Constr. 2011, 16, 291–308. [Google Scholar]

- Abdelhameed, W.A. Virtual Reality Applications in Project Management Scheduling. Comput. Aided Des. Appl. 2012, 9, 71–78. [Google Scholar] [CrossRef]

- Garg, A.; Kamat, V.R. Virtual prototyping for robotic fabrication of rebar cages in manufactured concrete construction. J. Archit. Eng. 2014, 20, 06013002. [Google Scholar] [CrossRef]

- Pang, X.; Nouidui, T.S.; Wetter, M.; Fuller, D.; Liao, A.; Haves, P. Building energy simulation in real time through an open standard interface. Energy Build. 2016, 117, 282–289. [Google Scholar] [CrossRef]

- Boton, C. Supporting constructability analysis meetings with immersive virtual reality-based collaborative bim 4d simulation. Autom. Constr. 2018, 96, 1–15. [Google Scholar] [CrossRef]

- Juan, Y.-K.; Chen, H.-H.; Chi, H.-Y. Developing and evaluating a virtual reality-based navigation system for pre-sale housing sales. Appl. Sci. 2018, 8, 952. [Google Scholar] [CrossRef]

- Rossado Espinoza, V.P.; Cardenas-Salas, D.; Cabrera, A.; Coronel, L. Virtual reality and bim methodology as teaching- learning improvement tools for sanitary engineering courses. Int. J. Emerg. Technol. Learn. IJET 2021, 16, 20. [Google Scholar] [CrossRef]

- Tea, S.; Panuwatwanich, K.; Ruthankoon, R.; Kaewmoracharoen, M. Multiuser immersive virtual reality application for real-time remote collaboration to enhance design review Process in the Social Distancing Era. J. Eng. Des. Technol. 2022, 20, 281–298. [Google Scholar] [CrossRef]

- Yu, H.; Chen, C. Automatic Generation of Civil Engineering Structure Model Based on Network Virtual Reality. Int. J. Glob. Energy Issues 2024, 46, 69–89. [Google Scholar] [CrossRef]

- Schiavi, B.; Havard, V.; Beddiar, K.; Baudry, D. A VR Training Scenario Editor for Operation in Construction Based on BIM 4D and Domain Expert Authoring. Smart Sustain. Built Environ. 2023, 12, 1074–1089. [Google Scholar] [CrossRef]

- Liao, J.; Lu, G. Research on Key Techniques of Virtual Reality Applied in Mining Industry. J. Coal Sci. Eng. 2009, 15, 445–448. [Google Scholar] [CrossRef]

- Tripathy, D. Virtual Reality and Its Applications in Mining Industry. J. Mines Met. Fuels 2014, 62, 184–195. [Google Scholar]

- Garrett, M.; McMahon, M. Computer-Generated Three-Dimensional Training Environments. Int. J. Gaming Comput. Mediat. Simul. 2010, 2, 43–60. [Google Scholar] [CrossRef]

- Nickel, C.; Knight, C.; Langille, A.; Godwin, A. How Much Practice Is Required to Reduce Performance Variability in a Virtual Reality Mining Simulator? Safety 2019, 5, 18. [Google Scholar] [CrossRef]

- Whyte, J.; Bouchlaghem, N.; Thorpe, A.; McCaffer, R. From CAD to Virtual Reality: Modelling Approaches, Data Exchange and Interactive 3D Building Design Tools. Autom. Constr. 2000, 10, 43–55. [Google Scholar] [CrossRef]

- Whyte, J. Industrial Applications of Virtual Reality in Architecture and Construction. Electron. J. Inf. Technol. Constr. 2003, 8, 43–50. [Google Scholar]

- Rubenstone, J. Mixing Reality on Site. ENR 2016, 277, 20–24. [Google Scholar]

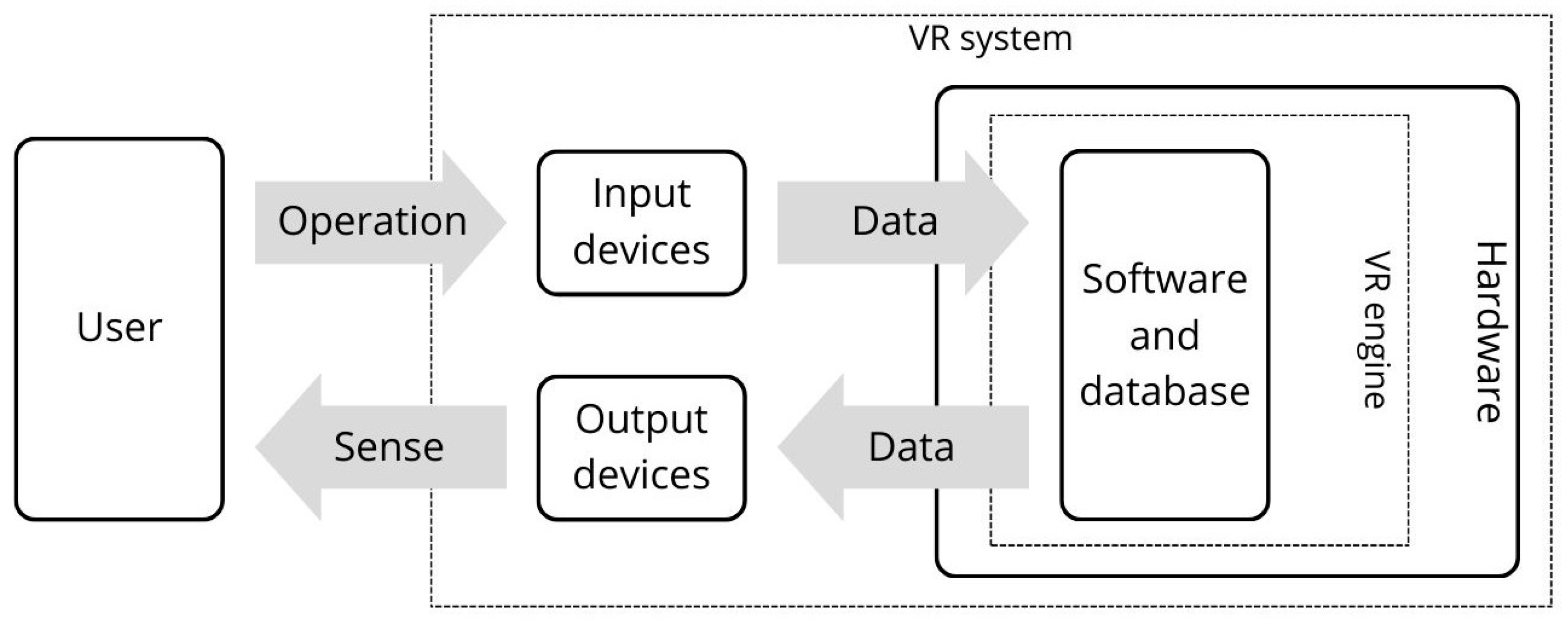

Elements of a VR system (own elaboration based on [3]).

Elements of a VR system (own elaboration based on [3]).

Table 1.

Keywords and search results.

Table 1.

Keywords and search results.

| Years | Keywords | |

|---|---|---|

| “VR OR Virtual Reality AND Mining Engineering OR Mining” | “VR OR Virtual Reality AND Civil Engineering OR Construction Industry” | |

| Number of Documents | ||

| 1990–1994 | 1 | 1 |

| 1995–1999 | 21 | 19 |

| 2000–2004 | 36 | 38 |

| 2005–2009 | 76 | 42 |

| 2010–2014 | 102 | 30 |

| 2015–2019 | 160 | 54 |

| 2020–2023 | 199 | 174 |

| Total | 595 | 358 |

Table 2.

Scientific publications on the application of VR technology in different areas of mining and civil engineering.

Table 2.

Scientific publications on the application of VR technology in different areas of mining and civil engineering.

| Area | Mining Engineering | Civil Engineering |

|---|---|---|

| Education | [3,13,14,15,16,17] | [18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37] |

| Occupational safety | [38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54] | [55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70] |

| Design, simulation and monitoring of technological processes | [3,17,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90] | [49,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108] |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

[ad_2]